Company Information

Ask for more detail from the seller

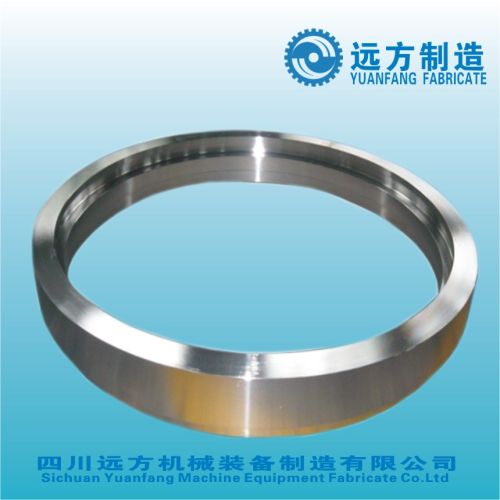

Contact SupplierWe are reckoned as a forged rings manufacturer.made from the best material, our forged rings comply with international standards.

salient features

•sturdy construction

•dimensional accuracy

•non- corrosive

•smooth functioning

•offer hassle free operation

•wear and tear resistant

•long operational life

seamless rolled ring forging process

i. Upsetting

the ring rolling process begins with the upsetting of the starting stock on flat dies at its plastic deformation temperature.

ii. Piercing

piercing involves forcing a punch into the hot upset stock displacing metal radially and leaving a thin web of metal at the bottom.

iii. Shearing

a subsequent operation, shearing, removes the thin web producing a completed hole through the stock.

iv. Preforming

this stock, referred to as a blank or preform, is now ready for the ring rolling process.

v.forming

the doughnut-shaped preform is placed over the mandrel.

as the preform is rotated in the mill, the mandrel begins to apply pressure toward the main roll. at the same time, the axial cones apply pressure toward each other.

as a result of the radial and axial pressure, the ring's od and id gradually increase while the thickness and wall section are reduced.

forged seamless rolled rings used in

ball and roller bearings

power transmission

power generation

textile machinery

pulp & paper

pressure vessel

wind turbine bearing

steel fabrication

aerospace industries