Company Information

Ask for more detail from the seller

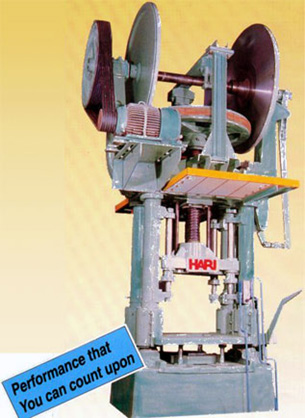

Contact SupplierThe 150T - Friction Screw Press designed & developed by Hari Machines Ltd. in the seventies is widely used for pressing all kinds of refractory materials. The superior performance & low maintenance requirements made it very popular even with the smallest of the refractory manufacturers. As of today about 300nos. of such presses are operating successfully with almost all refractory manufacturers in India.

Design - The press is closed frame construction consisting of base, head & coloumn rigidly clamped by tie rods.

Press Slide - The movement of press slide is guided by bushes moving over guide rods. This helps in avoiding any sizing problem in the moulds, particularly in the case of taper & key shaped bricks. This also minimises the chances of mould damage & reduces the incidence of rag rectification as well.

Floating Moulding Table - The mould table is suspended on four pneumatic cylinders & also firmly & properly guided in the columns. The table "FLOATS' during pressing to achieve the so called bottom pressing effect which improves the bulk density distribution from top to bottom of the brick.

Brick Ejection - Brick ejection is accomplished by pneumatic actuated slider-cum-locker mechanism. Ejection shaft lowering & lifting is contorolled by pneumatic valves.

Daspot Mechanism - Ejection shaft is connected to an oil daspot at the bottom to provide adequate cushioning effect during dropping of the bottom punch on the press bed.

Brake System - An effective brake system is incorporated by providing two spring loaded friction shoes which hold the flywheel in upper position in the pressing cycle. Effective functioning of the brake is ensured by proper adjustment in the operating mechanism.

Press Operation - Press up & down movement is accomplished by a operating handle with good leverage foreasy operation. Optionally pneumatic pressing system can also be supplied on request.