Company Information

Ask for more detail from the seller

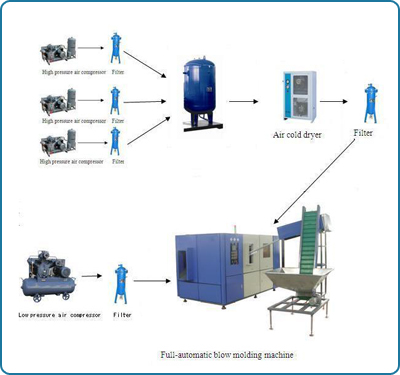

Contact SupplierMMB-L series full-automatic pet stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine. It has one to four cavities and the maximum capacity of the products is 2L. It can blow bottles in shapes: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET and PP etc.

Settings:

Features:

TYPE

| ITEM | MMBL

1500-2 | MMBL

2000-2 | MMBL

1500-3 | MMBL

1500-4 | MMBL

1500-6 | |

| CONTAINER | Number of cavity | 2 cavities | 2 cavities | 3 cavities | 4 cavities | 4 cavities |

| Output | 2200-2600 pcs/hr | 1700-2400 pcs/hr | 2800-3200 pcs/hr | 3800-4000 pcs/hr | 6000 | |

| Max.container volume | 1.5L | 2.0L | 1.5L | 1.5L | 0.7L | |

| Max.neck diameter | 38mm | 38mm | 38mm | 38mm | 38MM | |

| Max.container diameter | 90mm | 105mm | 90mm | 105mm | 60MM | |

| Max.container height | 330mm | 330mm | 330mm | 330mm | 265MM | |

| ELECTRICAL SYSTEM | Number of lamp | 32pcs | 32pcs | 40 pcs | 52 pcs | 6 |

| Max.heating power | 48kw | 48kw | 60kw | 63kw | 60 | |

| Installation power | 51kw | 51kw | 63kw | 78kw | 90KW | |

| Actual power consumption | 16kw | 16kw | 20kw | 24kw | 100KW | |

| AIR SYSTEM | Operatating pressure | 7kg/c㎡ | 7kg/c㎡ | 7kg/c㎡ | 7kg/c㎡ | 50KW |

| Low pressure consuming | 1100 Ltr/min | 1100 Ltr/min | 1400 Ltr/min | 2000 Ltr/min | 0.7Mpa | |

| Blowing pressure | ≤40kg/c㎡ | ≤40kg/c㎡ | ≤40kg/c㎡ | ≤40kg/c㎡ | 2000L/min | |

| High pressure consuming | 2000-2500Ltr/min | 2000-2500Ltr/min | 2000-3000Ltr/min | 3000-3500Ltr/min | 3.5Mpa | |

| CHILLER WATER | Operating pressure | 5-6 kg/c㎡ | 5-6 kg/c㎡ | 5-6 kg/c㎡ | 5-6 kg/c㎡ | 4500L/min |

| Temperatuer | 10℃ | 10℃ | 10℃ | 10℃ | 0.3-0.5Mpa | |

| Consuming | 5600kcal/hr | 5600kcal/hr | 7600kcal/hr | 7600kcal/hr | 10℃ | |

| Flow rater | 30Ltr/min | 30Ltr/min | 45Ltr/min | 45Ltr/min | 50L/min | |

| MACHINE | Machine dimension | 3.0×1.7×2.0(m) | 3.0×1.7×2.0(m) | 3.0×1.7×2.0(m) | 2.1×1.9×2.0(m) | 4.9×2.15×2.2 |

| Machine weight | 2.5ton | 2.8ton | 3.0ton | 3.2ton |