Company Information

Ask for more detail from the seller

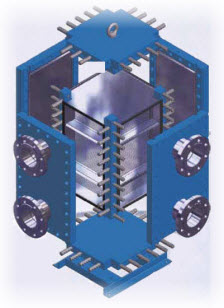

Contact SupplierThe HRSFUNKEBlock FPB and HRSFUNKEFlex FPF welded heat exchangers are the perfect solution when it comes to high temperatures and aggressive media. These types of heat exchangers are used, for example, in heat recovery or condensing processes in refineries, in the chemical and pharmaceutical industries and in a wide range of other industries. Due to their compact design, with very large heat transfer surfaces, these types of heat exchangers have extremely low space requirements and are also easy to service. The media used in the heat exchange process are supplied and drained through nozzles installed on the covers (FPF) or by casing plates (FPB). The media flows through the plate assembly in a cross flow / cross counter flow pattern, with heat from the hotter medium being transferred to the cooler medium. On account of the turbulent thin layer flow present, this heat transfer is substantially more effective than for other heat transfer models. Baffles can also be employed to ensure that the media pass through the heat transfer process repeatedly.

DESIGN

The plates of the FPB Heat Exchangers are based on the proven technology of the HRSFUNKE FP-series. A cassette is made of two corrugated heat exchanger plates which are assembled at an 180° angle to each other. Back to back these are laser welded along the sealing groove provided for the gasket. The aggressive medium or the refrigerant runs through the inlet aperture in this sealed flow channel between the plates. In the entry zone, the grooves of the plates have a special pattern so that the medium can freely run into the cassette. On the outside, each cassette is fitted with a gasket. When the critical medium passes from one cassette to the other, only two of the four ring gaskets at the apertures come into contact with the medium. These two ring gaskets are made from specially designed, highly resistant material. To ensure flawless sealing these specially designed gaskets are twice as thick as conventional gaskets. Furthermore, in the entry zone of the medium the profile of the gaskets are tapered onto the sealing ring and bridging piece. The flow gap of the less critical medium between the single cassettes is sealed with application specific gaskets of a proven quality. The gaskets are mounted with the completely reliable “T- Clip- System”. In the entry zone of each medium double welding seams and double gaskets between the cassettes guarantee for a leak free operation without any danger of mixing of the media

HRSFUNKE FLEX FPFDESIGN

The HRSFUNKEFlex is a welded plate heat exchanger with removable, sealed covers whose core consists of a welded plate assembly. Like all parts that come into contact with the media, this core is made of stainless steel and, in contrast to the standard casing, can be tailored to meet specific demands. The standardised design of the compact HRSFUNKEFlex stands out thanks to its flat cover, its extremely efficient heat transfer and its high, specific heat surface density m² / m³ of free space. A main feature of the FPF is also its ability to be easily cleaned. Using the types of plates available for welded plate assemblies - tubular, chevron and dimple, the demands dictated by the flow paths and properties of various media and applications can always be satisfied. Seals can be selected as appropriate, based on their resistance against the media or temperature.

TECHNICAL DATA: