Company Information

Ask for more detail from the seller

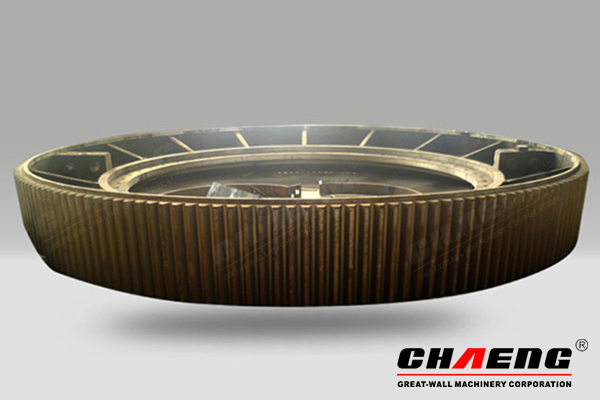

Contact SupplierGirth gear is an important transmission part of rotary kiln and ball mill equipment. The motor drives the pinion and pinion drives the girth gear mounted on the cylinder shell, because of this, the ball mill start driving. The girth gear is connected to the cylinder shell by bolt.

CHAENG can produce all kinds of large gear ring according to the drawings and sizes provided by customers.

According to the customer’s requirement, CHAENG chooses the appropriate wooden model for design and makes the CAE casting simulation before casting. The casting is strictly in accordance with the process of “wooden model—sand moulding—metallurgical casting—heat preservation—cleaning—heat treatment—rough finishing &fine finishing—package &delivery”, for the high quality gear castings.

1.High abrasion resistance

The CHAENG adopts unique heat treatment technology in casting, which optimizes the gear’s structure, improves its hardness, and greatly enhances its wear resistance and the impact force.

2. High strength steel ensures, long working time

The CHAENG uses the high-strength steel for gear casting, and optimize it according to the transmission characteristics of rotary kiln, ball mill which ensure its stability during long-time working and prolong the service life of the components.

3. Efficient mass production, shorten the delivery time

CHAENG has strong strength for steel casting parts, and can produce in large quantities with short production time and high output.