Company Information

Ask for more detail from the seller

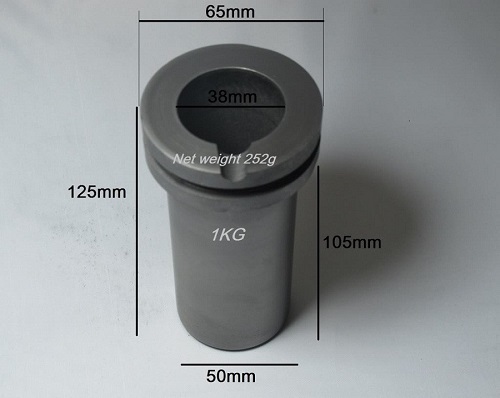

Contact SupplierWe are offering gold & silver melting graphite crucible

graphite materials

bulk density 1.80 gcm3 electric resistivity 15unm ash 0.1%

bending strength 65 mpa resist compression 60mpa particle 43um

application :melting or casting particular amorphous metals, rare metals and non-ferrous metals or alloys.

the crucible is equipped with pouring spout and double flanges.

Notes

1. Graphite crucible should be kept away from humid environment, and must be stored in a dry place or on a wooden shelf.

2. Handle it with care. Falling or shaking is strictly forbidden.

3. Roast it in drying equipment or by a furnace before use, wait till its temperature gradually rises to 500°c.

4. Crucible should be placed below the mouth of furnace to prevent the furnace lid abrading the upper edge of the crucible.

5. Feed materials according to the smelting capacity of crucible. It is not allowed to feed too many materials, in order to avoid crucible swelling.

6. The furnace discharging tools and clamps should comply with the shape of the crucible,

and use the tools to clamp the middle section of the crucible to prevent local stress from damaging the crucible.

7. Knock the crucible gently while removing slags and sticky cokes on the internal and external wall of the crucible. Don’t strike it heavily.

8. Keep appropriate distance between the crucible and the furnace wall. The crucible should be placed in the middle of the furnace.

9. Excessive use of combustion improver and additives will reduce the service life of crucible.

10. Rotate the crucible every week to extend its service life.

11. Prevent strong oxidation flame from reaching the side and bottom of the crucible directly.