Company Information

Ask for more detail from the seller

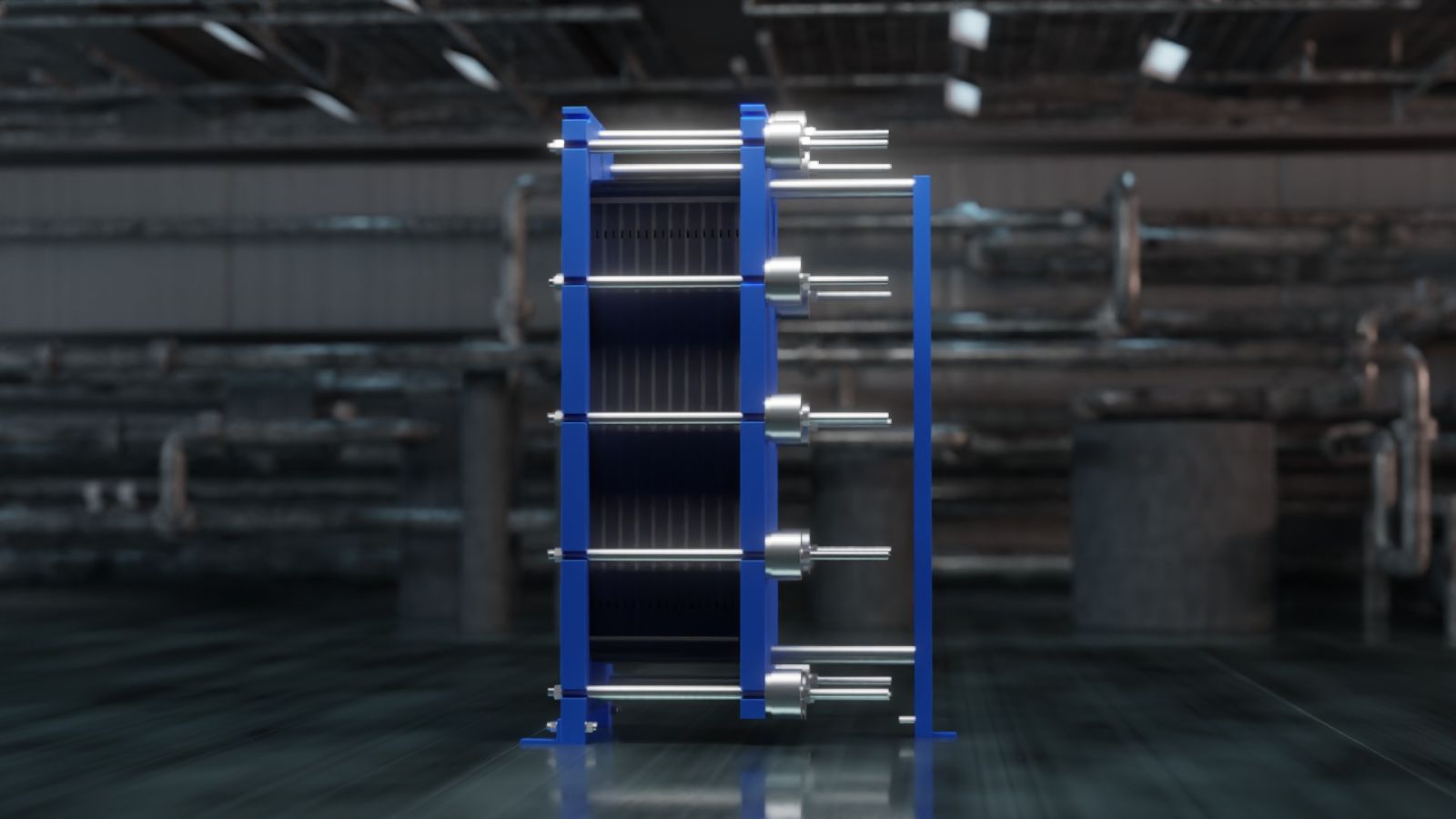

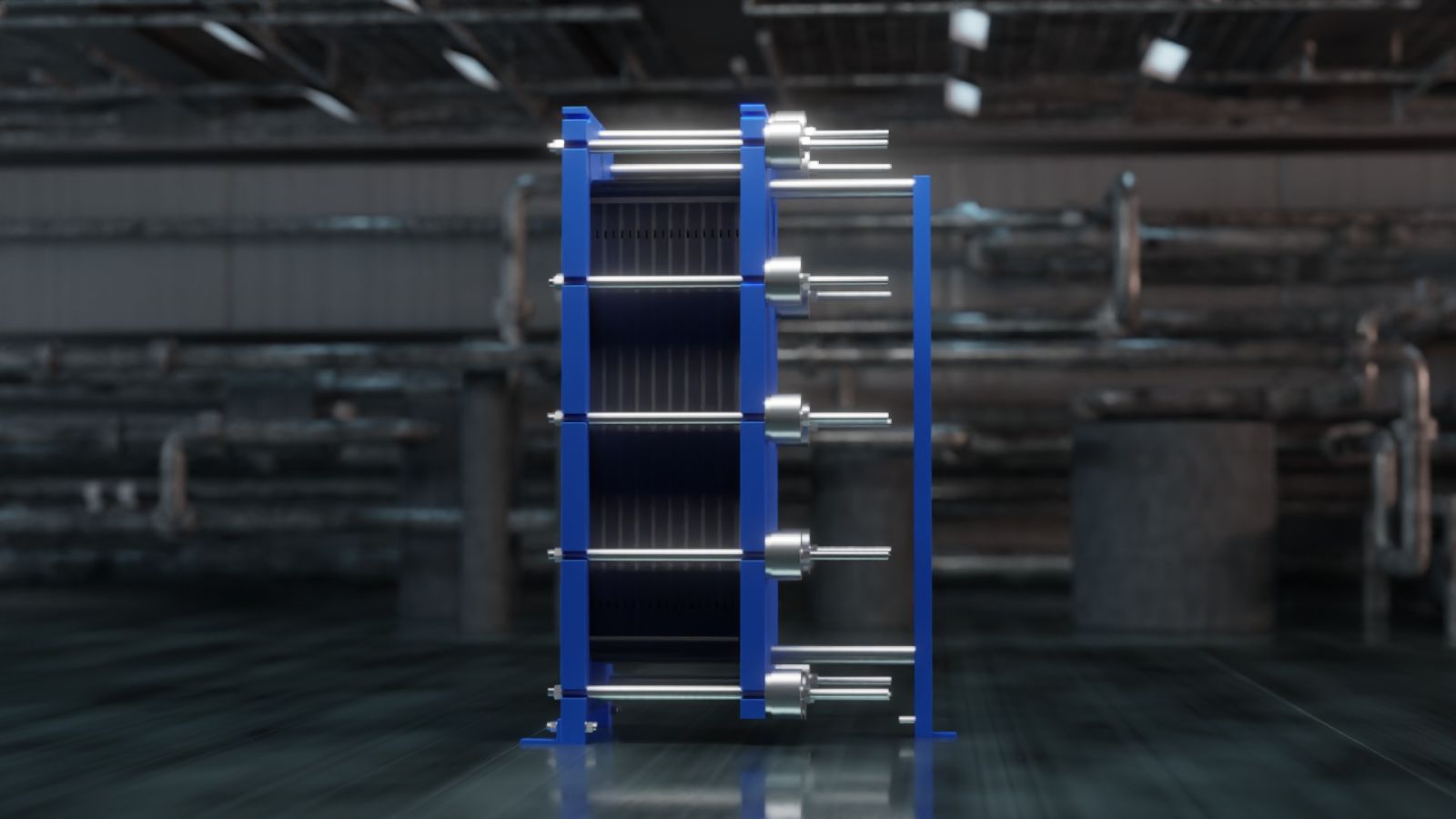

Contact SupplierGraphite Plate & Frame heat exchangers are designed to cool down or heat up ultra-corrosive chemicals. Safety, reliability, and performance in the long-term are our primary considerations when we size, design and manufacture our impervious graphite plate heat exchangers.

Key benefits:

Efficiency

2 to 3 times higher efficiency:

These units deliver 2–3 times greater efficiency compared to conventional heat exchangers, allowing for a much more compact design. The high internal turbulence significantly increases the film heat transfer coefficient, resulting in superior thermal performance.

Corrosion Resistance

Exceptional resistance to aggressive acids:

Our range of impervious graphite plate heat exchangers offers highly customized solutions for ultra-corrosive heat transfer applications. They provide excellent corrosion resistance to strong acids including HCl, HF, H₂SO₄, and HBr.

However, they exhibit limited resistance to oxidizing agents such as Cl₂ and high-concentration H₂SO₄ (above 65%), as well as caustic solutions like KOH and NaOH.

Modular Design

Ultra-compact and fully customizable:

Every impervious graphite plate heat exchanger is designed with a modular architecture, enabling precise adaptation to specific process requirements.

The number and dimensions of plates, along with process and service-side flow passes, can be customized to achieve optimal velocities, pressure drops, and heat transfer efficiency.

All graphite plates are precision-machined after impregnation, ensuring a perfectly smooth heat transfer surface and delivering excellent corrosion resistance along with long-term operational reliability.

Design:

Modular design: number of plates, size of plates and number of passes can be adjusted

Different plate sizes: GP 25 and GP 40

PTFE lined steel nozzles

Thermal expansion compensation ensured by helicoidal springs

MOC:

The material used for these heat exchangers is the same as that for block heat exchangers, with a high thermal conductivity of approximately 130 W/m.K.

GAB GPX 1, GPX 1T , or GPX 2 plates

Pressure plates and flanges: PTFE carbon steel

Tie rods, nuts, bolts, washers, springs: stainless steel

PTFE gaskets between the plates

Features:

Design pressure: up to 6 bars in standard

Design temperature: -30°C to +200°C (-22°F to 392°F)

Heat transfer area: up to 29m²

Nozzle sizes: DN80 / DN100 PN16

Design:according to European PED, ASME code on request