Company Information

Ask for more detail from the seller

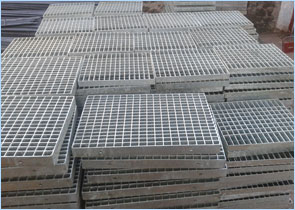

Contact SupplierFloor Gratings and Stair Treads by Neha Industries ensures easy and safe working, walking and wheeling surface. Bearing bars and cross bars are welded into one piece Grating with top of all bars being flush in one plane. Uniformity of material and design ensures trouble free services throughout the life of the Gratings. Factory tested and inspected Gratings gives the user full value for money.

Gratings by Neha Industries are precise, graceful and symmetrical. They are available in many classic patterns, all of which are designed for strength, uniform wear and attractive appearance. Gratings are available in rectangular and zig-zag pattern, with member size and center distances (pitch) as per loading conditions.

Gratings are mostly custom made as per the customers requirement and drawings. For the most techno-economical selection, specify NEHA INDUSTRIES for all your Gratings requirement. NEHA INDUSTRIES products are sold on the basis of guaranteed satisfaction to our valued customers.

FINISH Gratings are available in various finish as under: | ||

| SELF COLOURED For quicker deliveries to customers, Gratings can be delivered without any coating. Gratings can then be primed and painted at site. | ||

| RED OXIDE Gratings can be primed with red oxide for protection during transit and storage at site, before installation. | ||

| PAINTED Gratings can be primed and finish painted as per customer's requirement and specifications. | ||

| HOT DIP GALVANIZED Gratings can be Hot Dip Galvanized as per Indian Standards (ISI), for protection from corrosion in damp environment. | ||

| BEARING BAR SIZE (mm) | SPAN (mm) | 400 | 600 | 800 | 1000 | 1100 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 |

| LIMITING DEFLECTION (mm) | 1.4 | 2.0 | 2.7 | 3.4 | 3.7 | 42 | 5.0 | 5.9 | 6.7 | 7.5 | 8.4 | |

| 25 x 3 | UDL | 3492 | 1478 | 841 | 542 | 443 | 343 | |||||

| CI | 2182 | 923 | 525 | 338 | 276 | 214 | ||||||

| 25 x 5 | UD L | 5820 | 2463 | 1403 | 904 | 739 | 572 | 394 | ||||

| CI | 3637 | 1539 | 876 | 565 | 461 | 357 | 246 | |||||

| 30 x 3 | UDL | 6035 | 2554 | 1454 | 938 | 766 | 593 | 408 | ||||

| CL | 3771 | 1596 | 908 | 586 | 478 | 370 | 255 | |||||

| 30 x 5 | UDL | 10058 | 4257 | 2424 | 1563 | 1278 | 988 | 681 | 506 | |||

| CI | 6286 | 2660 | 1515 | 976 | 798 | 617 | 425 | 316 | ||||

| 35 x 3 | UDL | 9576 | 4053 | 2308 | 1488 | 1216 | 941 | 648 | 481 | |||

| CL | 5985 | 2538 | 1442 | 930 | 760 | 588 | 405 | 300 | ||||

| 35 x 5 | UDL | 15969 | 6759 | 3849 | 2482 | 2029 | 1569 | 1081 | 803 | 611 | 480 | |

| CL | 9980 | 4224 | 2405 | 1551 | 1268 | 980 | 675 | 501 | 381 | 300 | ||

| 40 x 3 | UDL | 14306 | 6055 | 3448 | 2223 | 1818 | 1406 | 968 | 719 | 547 | 430 | |

| CL | 8941 | 3784 | 2155 | 1389 | 1136 | 878 | 605 | 449 | 341 | 268 | ||

| 40 x 5 | UDL | 23846 | 10093 | 5748 | 3706 | 3030 | 2344 | 1614 | 1200 | 912 | 717 | 586 |

| CL | 14903 | 6308 | 3592 | 2316 | 1893 | 1465 | 1008 | 750 | 570 | 448 | 366 | |

| 50 x 5 | UDL | 46566 | 19710 | 11225 | 7237 | 5917 | 4577 | 3153 | 2343 | 1782 | 1401 | 1144 |

| CI | 29103 | 12318 | 7015 | 4523 | 3598 | 2860 | 1970 | 1464 | 1113 | 875 | 715 | |

| Note : Spans to left of heavy line in table A & B produce a deflection of 6 mm or less under a uniform distributed load of 500 kg/sq.m. | ||||||||||||