Company Information

Ask for more detail from the seller

Contact SupplierSpecifications

1.structure:basic material, finish & back finish

2.basic material: e1 mdf, fr mdf,

3.front finish: melamine

4.back finish: black acoustic felt

5.standard size: 2440 * 128 , 2440 * 192 mm, etc.

6.standard thickness: 12 15 18 mm

7.standard pattern: 28-4

8.installation: ( 1 ) light weight steel keel system ( 2 )wooden pattern system

9.fire rate: can meet china standard class b1 and bs476 part 7 class 1

10.eco level: can meet china and eu standard class e1

11.applications: gymnasium, hotels, exhibition centers, schools, studio etc.

12.customized or not: can be customized

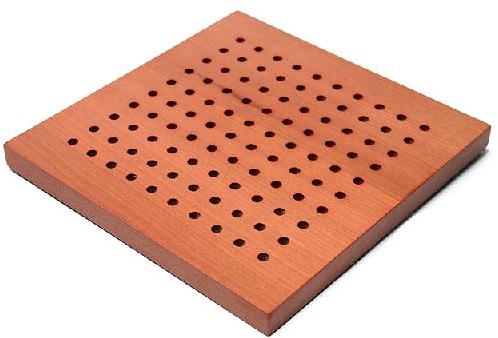

our wooden grooved acoustic panels consist of three layers: the substrate, the front surface and the back surface. We use mdf as the substrate, which is laminated with melamine or natural wood veneer on the front surface, channeledslotted with a series of grooves on the front surface, perforated with a series of round holes on the back surface and then a layer of black acoustic fleece is pasted on the back surface of the substrate.

The pattern of our wooden grooved acoustic panels is determined by the width of the slats and grooves. For example, pattern 13-3 means the width of the slats is 13mm and that of the grooves is 3mm.

Our wooden grooved acoustic panels have excellent sound absorbing performance, especially on low and middle-frequency sound.

So far, our wooden grooved acoustic panels have been sold nationwide and exported to southeast asia, europe, america, etc.

They are widely used in the following four kinds of places as walls and ceilings:

* places that require high quality sound effect, such as studios, recording rooms, listening rooms, rehearsal rooms and so on;

* places of public entertainment, such as theaters, cinemas, indoor stadiums, dancing halls, ktv rooms, etc.

* places where keep secret or quiet is needed, such as meeting rooms, office.