Company Information

Ask for more detail from the seller

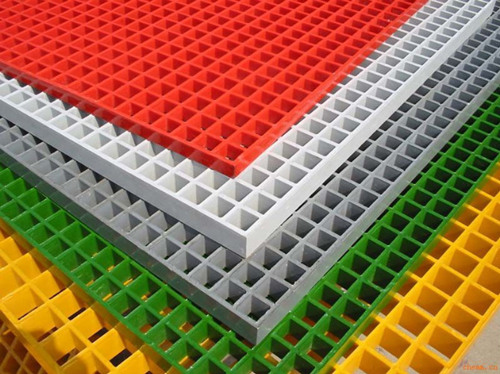

Contact SupplierFRPGRP molded grating use high strength fiberglass roving as reinforcing material, together with unsaturated polyester resin. FRP GRATING has the best bi-direction mechanical properties, with good chemical resistance can be achieved by using superior polyester resin. FRP molded grating are widely used in the power generation, sewage treatment, oil refining and oceanographic survey fields as work floors, stair treads, and trench covers for loading frames. Apart from standard panels.

we can also produce gratings of different thickness, mesh and panel size. Surfaces available include concave top, smooth grating, gritted top, covered with grit, flat or decorative plating, etc

Features

1. Corrosion Resistance

Different types of resin provide their own different anti-corrosion properties, which could be used in different corrosion circumstance such as acid, alkali, salt, organic solvent (in gas or liquid form) and the like over a long period.

2. Fire Resistance

Our special formula provide grating with excellent fire resistant performance. Our FRP gratings pass ASTM E-84 Class 1.

3. Light Weight & High Strength

The perfect combination of the continuous E-glass roving and thermosetting polyester resin provide grating with light weight and high strength and its specific gravity is only 14 of that of steel, 13 of aluminum. Its rigidity is up to and even exceeds that of steel. Different thickness and mesh size bring the client more choice.

4. Safety & Anti-slip

The high modulus of elasticity and various surfaces provided the super anti-skid performances. Its surface could be smooth surface, meniscus surface, grit surface and chequer plate cover which is suitable for different working places.

5. Electrical Insulating

High strength E-glass roving and high-grade resin provide the product super electric performance. Its electric break strength could reach 10KVmm.