Company Information

Ask for more detail from the seller

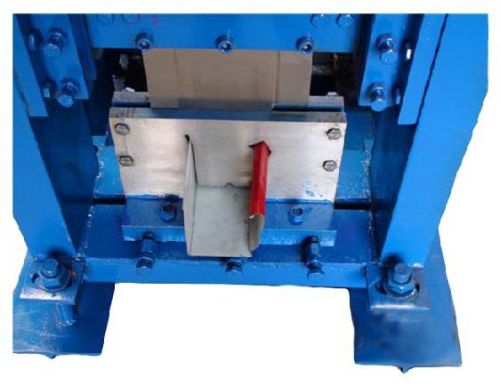

Contact SupplierGutter cold roll forming machine the components of gutter cold roll forming machine: uncoiler, the feed leading table, the main machine, the formation cutting device, hydraulic system, control system and the product bracket. We have professional team to make different kinds of roll forming machines for our customers, from designing, processing, assembling, debugging, delivery. You can come to our factory and we will teach you how to operate the machine for free. Technical: (1) manual decoiler un-powered; single head; max. Capacity: 5000kg; coil inner-diameter: 508mm (2) roll-forming mc: roller material: 45# steel voltage: 380v50hz (3) cutting mechanism it adopts hydraulic drive and automatic location to decide the dimention and cut the target products. match equipment: one set of cutting tool, one hydraulic tank, one cutter machine. stop to cut, post cut cutting length tolerance: ± 2mm cutting tool material: gcr12 with quenched treatment 60-62° c (4) hydraulic system it is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job. match equipment: a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves. (5) computer control cabinet: it adopts taida plc to control. The target piece length is adjustable and digit of it can be adjusted.