Company Information

Ask for more detail from the seller

Contact SupplierA successful product could be defined as one, which consistently meets the requirement of the key member of the value chain. PPr for plumbing and heating applications is a good example of this. It offers, for instance to the converters easy process ability to both pipes and fittings to system suppliers proprietary colours, to the installer excellent weldability and to the building owner no taste and odour influence, long service lifetime and excellent environmental LCA results.

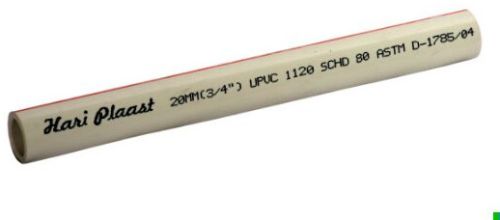

Polypropylene homopolymer, PP-H (or PP type 1) is made by polymersing propylene in the presence of a catalyst at moderate temperatures and pressures. By introducing ethylene as a co monomer during the polymerisation, polypropylene copolymer, PP-C can be produced. The monomers are built into a range of molecular weights during copolymerisation and using modern catalyst and polymerisation techniques, molecular weight distribution and molecular configuration can be carefully controlled. The ethylene can be introduced in blocks and with a higher percentage for what is classified as a “Block- Copolymer”, PP-B (or PP type 2) or at random and more dispersed for a “random copolymer”, PP-R (or PP type 3). The latter, more recent development has been further improved to obtain the best long-term heat stability, slow crack growth resistance performance and welding performance. Due to superior physical characteristics of PPr material such as working temperatures up to 95o C along with superior chemical resistance providing definite solution to oxidation and calcification, make PPr an ideal material, primarily for hot and cold water plumbing systems in buildings and industrial piping installations. Besides sanitary systems this material is used for varieties of applications like air distributions, radiator heating etc.

Features and Benefits

PPr raw material is hydrocarbon polymer made up basically of hydrogen & carbon which are non toxic. Density is 0.89 – 0.92g / cm3 PPr has a vicot softening point.

| Outside diameter | Wall Thickness of pipes for pressure rating

| |||

|---|---|---|---|---|

| Min | Max | SDR 11/PN 10

Wall Thickness | SDR 7.4/PN 16

Wall Thickness | SDR 6/PN 20

Wall Thickness |

| 16.0 | 16.3 | – | 2.3 | 2.7 |

| 20.0 | 20.3 | 1.9 | 2.8 | 3.4 |

| 25.0 | 25.3 | 2.8 | 3.5 | 4.2 |

| 32.0 | 32.3 | 3.0 | 4.5 | 5.4 |

| 40.0 | 40.4 | 3.7 | 5.6 | 6.7 |

| 50.0 | 50.5 | 4.6 | 6.9 | 8.4 |

| 63.0 | 63.6 | 5.8 | 8.7 | 10.5 |

| 75.0 | 75.7 | 6.9 | 10.4 | 12.5 |

| 90.0 | 90.8 | 8.2 | 12.5 | 15.0 |

Pipe Dia (mm) | Welding Depth (mm)

| Heating Time (sec) | Welding Time (sec) | Cooling time (sec) |

|---|---|---|---|---|

| 20 | 14.50 | 6 | 4 | 2 |

| 25 | 16.00 | 7 | 4 | 2 |

| 32 | 18.00 | 8 | 6 | 4 |

| 40 | 20.50 | 12 | 6 | 4 |

| 50 | 23.50 | 18 | 6 | 4 |

| 63 | 27.50 | 24 | 8 | 6 |

| 75 | 30.00 | 30 | 8 | 6 |

| 90 | 37.00 | 40 | 8 | 6 |