Listing ID #3844793

Company Information

Ask for more detail from the seller

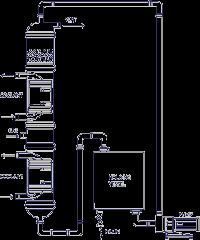

Contact SupplierHydrogen Chloride gas produced as a by product can be economically processed into Hydro – Chloric Acid by simple Absorption Adiabatic Absorption is the most effective means of production of Hydro – Chloric Acid solution. Under normal operating conditions Hydro Chloric Acid Solution of 30% – 31% strength can be obtained.

These absorbers operate, as the name implies, without any heat input into the reaction zone.

The gas loading should in no case fall below 50% of the design maximum for adiabatic absorption column to be most effective means of absorption.

In this process HCL – Gas is absorbed by fresh water flowing down the column . The heat generated by this reaction vapourises approximately 30% of the water that rises to the head of the column with non – soluble components of the gas stream.

Hydrogen Chloride streams containing air, water vapour & non – condensable are condensed / absorbed within the column and are returned together with the make up water to the bottom of the column through several packed sections and are passed through heat exchangers for dissicipatcing the heat of absorption before storage. The acid out let temperature is 45° C to 50°.