Company Information

Ask for more detail from the seller

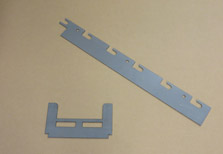

Contact SupplierAt S&R, Inc., we are recognized for our production of precision fabricated parts, catering to customers across a range of industries. In the project highlighted here, we were commissioned to create steel components for a customer in the heavy automotive machinery industry. These upper rail parts are used in the manufacturing of Kanban rack systems. Employing 11 gauge HRPO steel and our state-of-the-art CNC laser cutter, the parts were precision laser cut to the customer requirements as outlined in the supplied 2D CAD drawings. A tight ± 0.005” tolerance was met during manufacturing. Our laser process produced burr-free parts without any material deformation. In process and postproduction testing was implemented to ensure quality and accuracy, including visual and dimensional inspection methods.

Dimensions of the completed parts were 5.5” x 9.5” and 4” x 24”. This project was completed within 2 weeks and shipped to the customer in Kentucky in 1525 unit orders. For more details about this custom laser cutting project, or any of our capabilities in precision sheet metal fabrication please see the table below or contact us directly.