Listing ID #7037629

Company Information

Ask for more detail from the seller

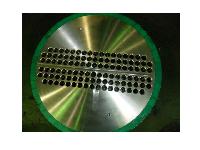

Contact SupplierAs the name suggests, in this type of Fin Tube the finning is a Spirally Wound.

The fins are manufactured by Spirally Winding the fin around the Base Tube and Pipe. During the winding the fin is Continuously Welded by High Frequency welding giving the Most robust bond between the the Fin and the Tube.

This type of Fin Tube is used specifically where the application involves a lot of Mechanical Stresses like continuous vibrations etc.

The welding bond between the Tube and The Fin also ensures that almost perfect heat Transfer Efficiency is achieved. Also it can give the highest operating temperature ranges.

These Fin Tubes find application in RADIATORS, AIR PREHEATERS, WASTE HEAT RECOVERY SYSTEMS, & BOILER FIN TUBES etc and are preferred in Industries like Power Plants, Chemical Industries, Steel Plants, and Chiller Plants etc.

Manufacturing Range (Welded Fin Tube/Solid Fin Tube):-

|

Sr. No |

Particulars |

Range |

|

1 |

Base Tube Material |

Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Copper, Duplex Stainless Steel, and Inconel etc. (all material in the theoretical limit) |

|

2 |

Base Tube Outside Diameter |

16.00 mm to 225.00 mm (½” NB Pipe to 8” NB Pipe) |

|

3 |

Base Tube Thickness |

2.50 mm And Above |

|

4 |

Base Tube Length |

500 mm Min To 12000 mm |

|

5 |

Fin Material |

Carbon Steel, Alloy Steel & Stainless Steel |

|

6 |

Fin Thickness |

0.80 mm To 2.50 mm |

|

7 |

Fin Density |

79 FPM (2 FPI) to 276 FPM (7 FPI) |

|

8 |

Fin Height |

9.8 mm to 25.00 mm |

|

9 |

Bare Ends |

As per Client Requirement |

|

10 |

Manufacturing Capacity |

3,00,000 Meter Per Annum |

We can supply material on urgent delivery basis because of large stock and relations with raw material suppliers. We use only Prime Quality base tube and Aluminum Material.

Established in the year 2019, we at Fitzer Incorporation are one of the most renowned and reputed manufacturers, suppliers, and exporters of industrial equipment. We proficiently deal in Heat Exchangers, Heating Process Equipment, Cooling Process Equipment, Desiccant Dehumidifier, IQF Tunnel Freezer, Cold Storage Room, Convection Recuperator, Pressure Vessels, Storage Tanks, and Thermal Energy Storage systems. All of our products are manufactured and designed as per the global standard such as API, ASME, IBR, TEMA, and ASHRAE.

We have established world-class transportation equipped with advanced and newest technology machines that assists us in organizing the products with dimensionally accurate, extremely efficient, highly durable, corrosion-resistant, and strong construction. Moreover, with the highly demanded items, we give properly planned fabrication-erection services for industrial plants by offering system designs, fixing, and after-sales services.

We have appointed a team of professionals and well-trained experts who are aimed to create machines to manufacture products from the best quality raw materials following the best industry terms and norms.

Our team of quality controllers performs a series of tests to inspect the overall quality and operations of the products.

Fitzer Incorporation is working under the able motivation and guidance of Mr. Siddhi Chavan. Since our beginning, we have followed the policy of blending price and quality for offering the best possible items to valuable customers. We aim to increase our business shortly while keeping up our striking track record.