Company Information

Ask for more detail from the seller

Contact SupplierA. Products Precision

Precision Is The Key Requirement For Adjusting Shims. And Can Control Product Precision Dimension Within 0.002mm,We Finish Grouping By Inspecting One Products Inside Dust-Free Workshop. One Product Is Measured For No Less Than 5 Times From Finishing Process To Finished Product.

B. Geometric Tolerance

We Adopt High-Precision Double-Sided Lapping Machine To Ensure And Control Depth Of Parallelism For Products Within 0.002mm.Adoption Of One-Time Forming Process Better Ensures Product Axiality

C. Material Quality And Hardness

We Choose High Quality Material And Advanced Thermal Treatment Equipment /Technology

D. Cleanliness

Product Cleanliness Can Be Better Ensured Due To Multi-Channel Ultrasonic Cleaning, Dust-Free Workshop Package And Plastic Case Sealed.

Technical Parameters

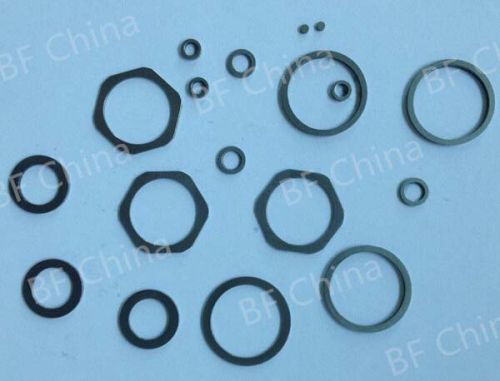

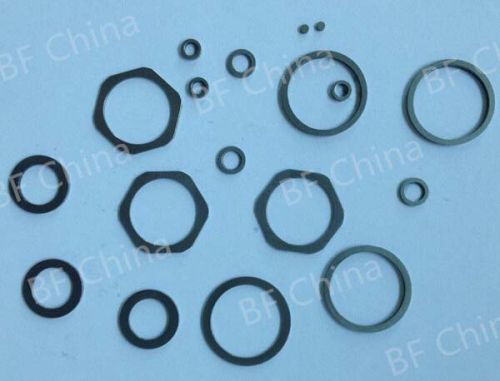

600 pieces diesel common rail repair tool bosch injector shim kits

B11 CRIN1 Air clearance shims(1.200-1.380).................... 10classes*5pcs

B12 CRIN1 Armature lift shims(0.950-1.140).................... 20classes*5pcs

B13 CRIN Solenoid valve spring shims(1.380-1.560).......... 10classes*5pcs

B14 Full range of nozzle spring shims(1.200-1.580)........... 20classes*5pcs

B16 CRIN2 Needle lift shims(1.090-1.290)......................... 10classes*5pcs

B22 CRIN2 Cushion lift shims(0.990-1.170)........................10classes*5pcs

B25 CRI Air clearance shims(0.960-1.140)..........................10classes*5pcs

B26 CRIN2 Armature lift shims(1.560-1.600).......................5classes*10pcs

B31 CRI Armature lift shims(1.200-1.290)...........................10classes*5pcs

B48 CRI Solenoid valve spring shims(1.380-1.560)..............10classes*5pcs

Total 115 classes 600pcs