Company Information

Ask for more detail from the seller

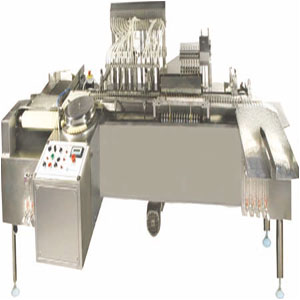

Contact SupplierHigh Speed Automatic Ampoule Filling & Sealing Machine is compact & versatile machine for the filling & sealing of glass ampoules. Our Automatic Eight Head Ampoule Filling & Sealing Machine provides output up to 12000 ampoules per hour and having usage in large batch production of injectables. Apart from the pharmaceuticals, this machine can also be useful for large scale production of cosmetics. Machine complies as per cGMP requirements and having crucial part of Injectable Ampoule Filling Line.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||