Company Information

Ask for more detail from the seller

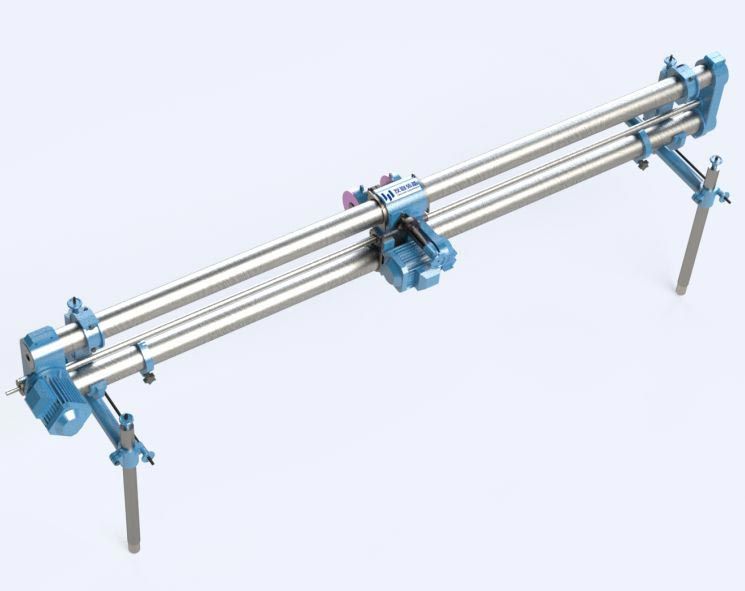

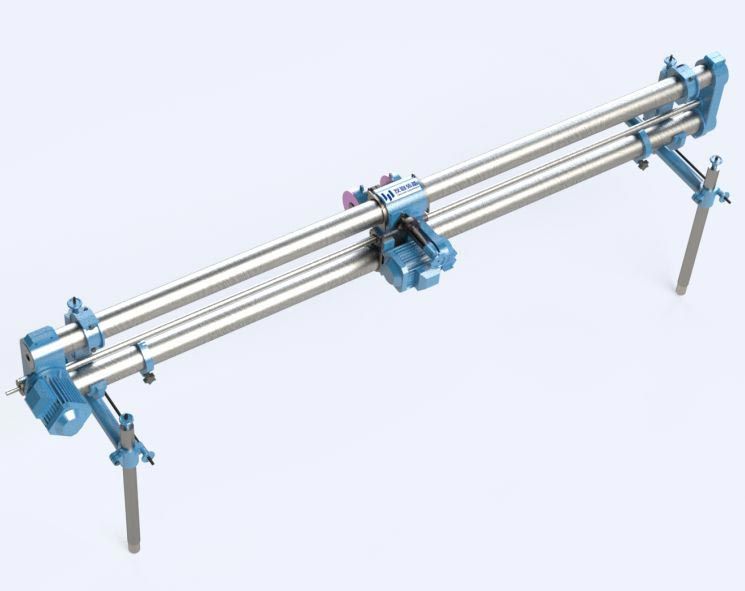

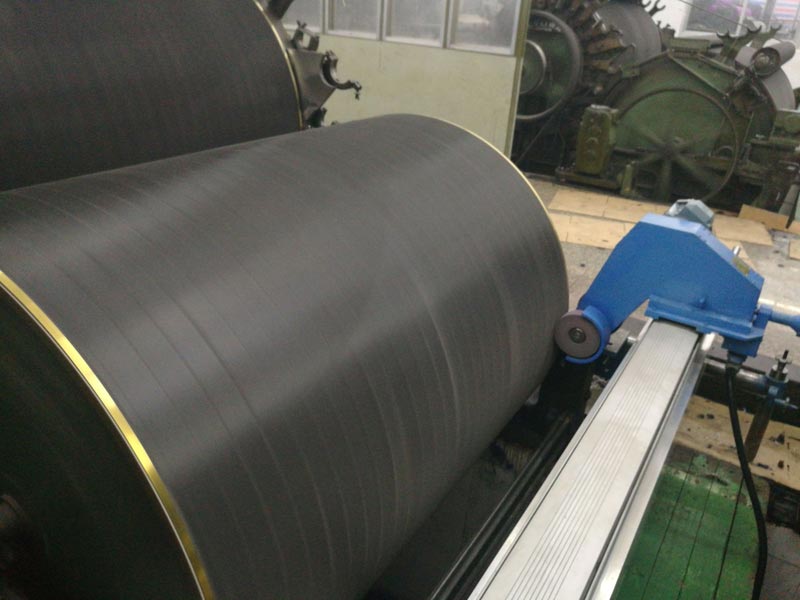

Contact SupplierThe status of the wool card clothes can affect the quality of the yarns. To improve the quality and efficiency of grinding wool card clothes, we have introduced the high-speed grinding machines which are widely applied in the wool textile industry and thus consequently enhance the yarn quality.

Product advantage

Suitable for a series of carding machines.

With the function of surface grinding, side grinding and polishing.

Stable quality、high precision、convenient use、high speed grinding machine solutions.

The reciprocating guideway is not easy to be abrased,the structure is simple, the maintenance cost is low.

Product function

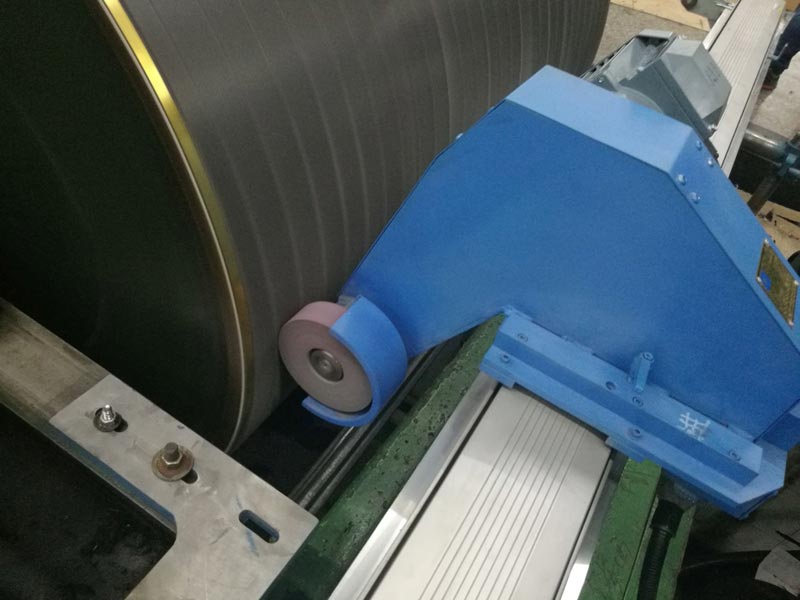

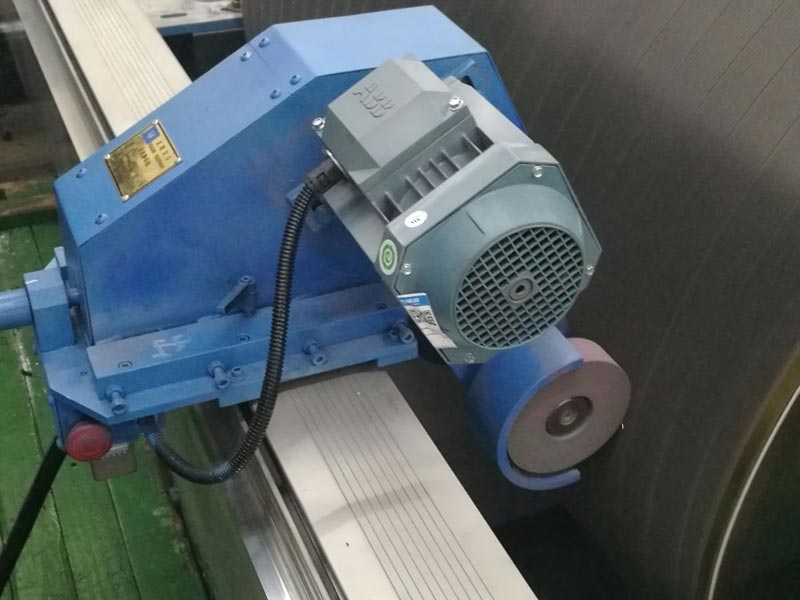

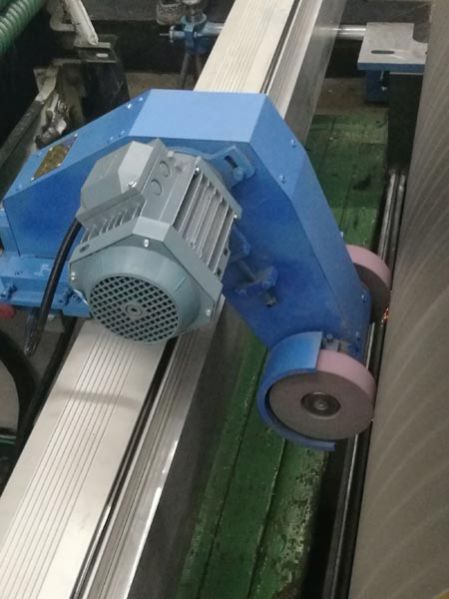

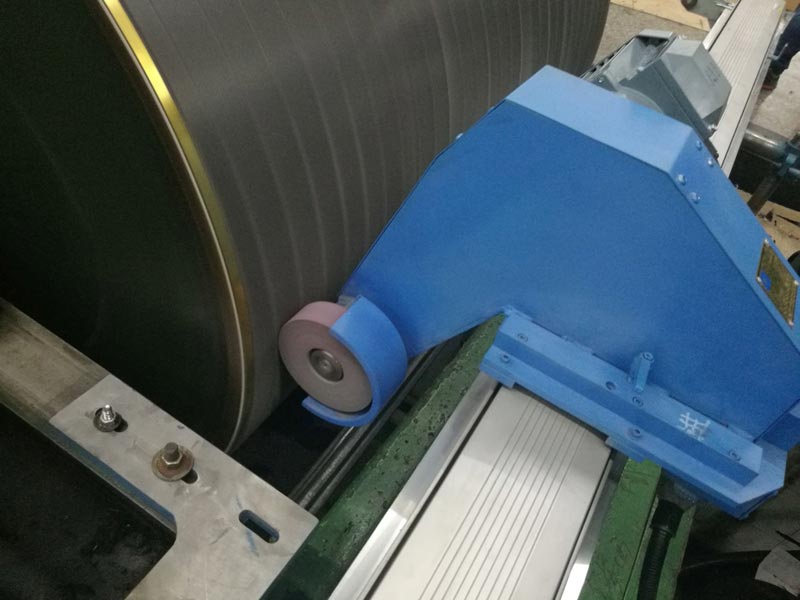

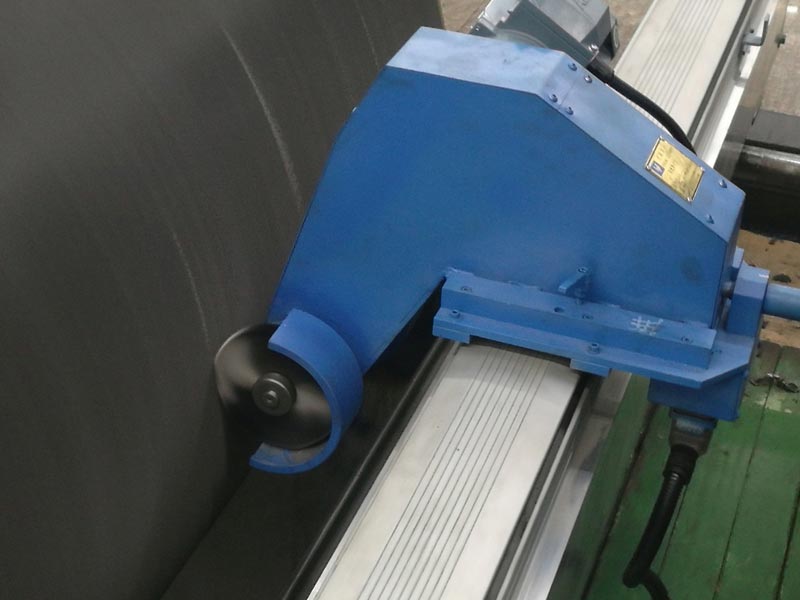

Surface grinding function : The steel needle on the elastic needle cloth can be made smooth after the change of the angle on the elastic cloth, and the angle of the steel needle is always the same. The actual operation as shown in the figure, the grinding head conducts reciprocating motion, grinding wheels are installed respectively on the grinding wheel shaft at two sides of the grinding head.

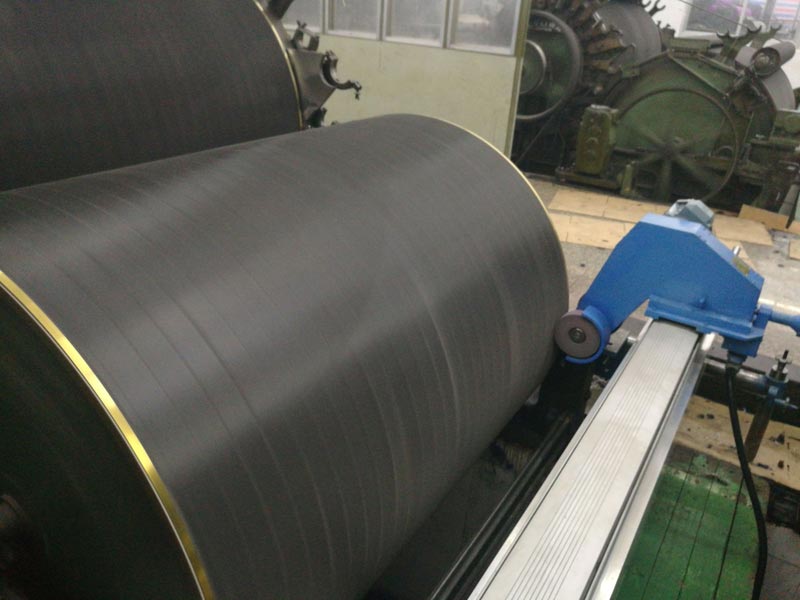

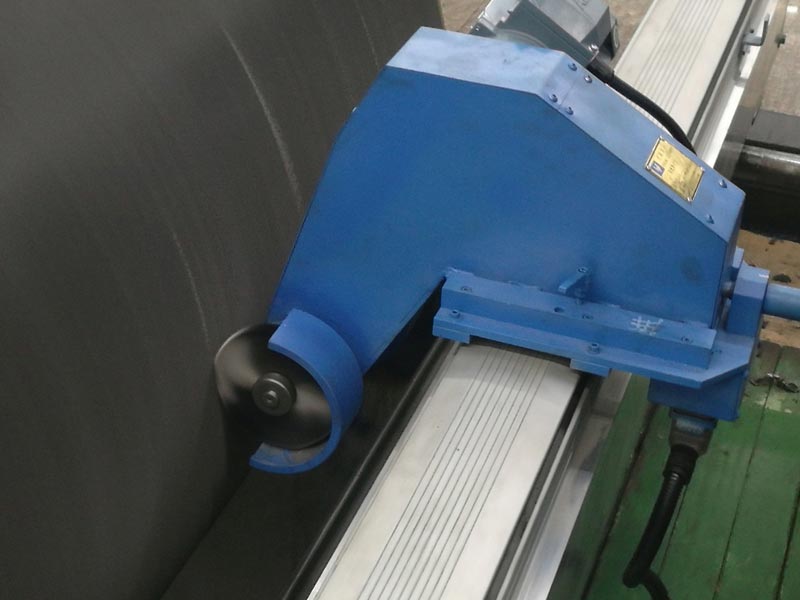

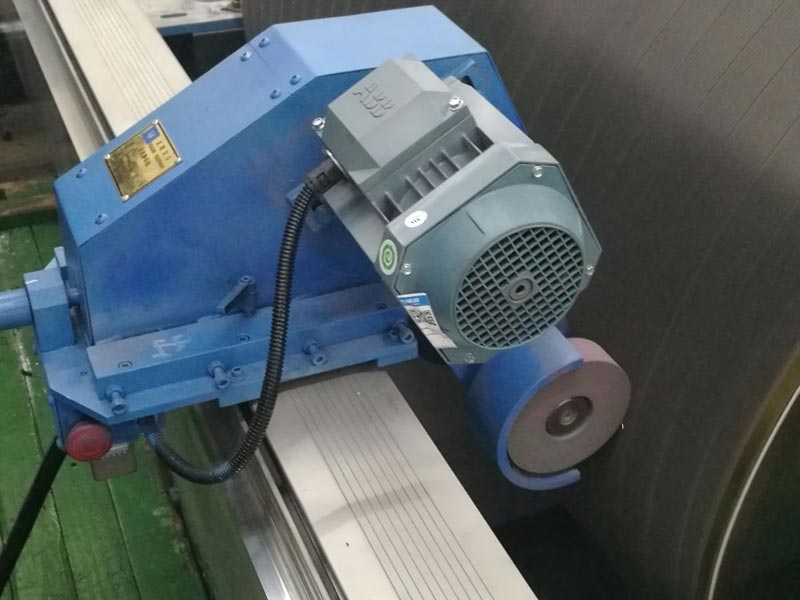

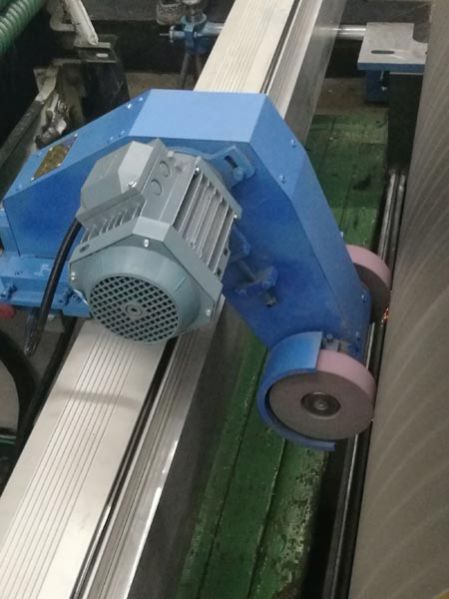

Side grinding function : After surface grinding process onto the elastic cloth needle. The process of side grinding can be conducted onto the side of the needle, the sharpness of the needle top will be restored after this process. The actual operation as shown in the figure, the grinding head conducts reciprocating motion,2 groups of side grinding wheels are installed respectively on the grinding wheel shaft at the both sides of grinding head, each group has 4 side grinding wheels. The side grinding wheels are inserted into the space between needles and frict the upper part of the needles with high speed rotation to realize the sharpness requirements.

Polishing function : After side grinding process onto the upper part of the needles . The process of polishing can be conducted onto the needles in order to eliminate the burrs. The actual operation as shown in the figure, the grinding head conducts reciprocating motion,2 groups of polishing brushes are installed respectively on the grinding wheel shaft at the both sides of grinding head, each group has 4 polishing brushes. The polishing brushes are inserted into the space between needles and frict the upper part of the needles with high speed rotation to realize the smooth requirements.

Scope of application : Used in a series of carding machines

| Type : | FJ-MZJ-80 | FJ-MZJ-100 |

|---|---|---|

| Grinding length max : | 2000mm | 2500mm |

| Weight : | 400kg | 420kg |

| Length : | 3300mm | 3800mm |

| Grindin straightness error : | <0.05 | |

| Lateral movement speed of grinding head : | 0~285mm/min | |

| Linear speed of grinding wheel : | 31m/ses | |

| Function set : | surface grinding、side grinding、polishing | |

| Surface grinding wheel : | sizeØ150*36* Ø20 made in Italy,particle size 46 | |

| Side grinding : | size Ø150*1.5* Ø60 made in Italy,particle size F180 | |

| Polishing wheel : | size Ø150*5* Ø20 made in Italy,Iron wire dia.Ø0.1 | |

| Installed power : | 2kw | |

| Electrical machine : | ABB electrical machine | |

| Control system : | Mitsubishi PLC and transducer;electrical apparatus element of Schneider | |

| Safety precautions : | Reciprocating device fault alarm | |

| Type : | YX0003-80 | YX0003-100 |

|---|---|---|

| Grinding length max : | 2000mm | 2500mm |

| Weight : | 150kg | 170 kg |

| Length : | 3300mm | 3800mm |

| Grindin straightness error : | <0.02mm | |

| Lateral movement speed of grinding head : | 0~285mm/min | |

| Linear speed of grinding wheel : | 31m/ses | |

| Function set : | surface grinding、side grinding、polishing | |

| Surface grinding wheel : | size Ø150*36* Ø20 made in Italy,particle size 46 | |

| Side grinding : | size Ø150*1.5* Ø60 made in Italy,particle size F180 | |

| Polishing wheel : | size Ø150*5* Ø20 made in Italy,Iron wire dia Ø0.1 | |

| Installed power : | 1.3kw | |

| Electrical machine : | A asynchronous AC motor is used in the grinding wheel and the servo motor is used in the transverse part. | |

| Control system : | Mitsubishi PLC and transducer & Servo driver; electrical apparatus element of Schneider | |

| Safety precautions : | Reciprocating device fault alarm | |