Listing ID #3894215

Company Information

Ask for more detail from the seller

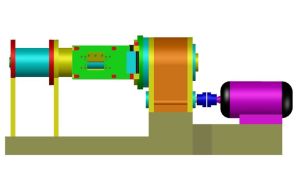

Contact Supplier“G. G. Hot Feed Extruders” are ideally suited for production of Rubber Chords, Rubber Strips, Rubber Profiles, Rubber Tubing, Rubber Channels, Rubber Treads and are Specially designed for meeting the need for efficient and quality extrusions.

G. G. Engineering Works based in Mumbai, India, offers a vast range of Hot Feed Rubber Extruders in size 40, 56, 63, 75, 100, 110 & 150 mm or different applications, such as Tread, Tubes, Profiles, Hoses, Sheeting with Roller die head, Cable coating, Dock Fenders, Straining of Raw materials, Press blanks, pre-warming for Calendar feeding, Inner tubes for Bicycle, cars and Trucks.

Manufacturers of Hot Feed Rubber Extruder Mumbai India

L/D Ratios : 4:1/ 6:1/8:1

MATARIAL FEED : Tangential under cut Hopper & Feed Roll Device.

DRIVES : Constant Speed or variable speed.

HEADS : STRAIGHT HEADS for Tube, Profile, Rods etc.

CROSS HEAD for second coating of pre-extruded section like Hoses, Profile etc.

STRAINER HEADS for filtering the compounds.

TREAD HEADS for Treads & Camel - back.

CO-EX HEADS for extruding multiple components in one go.

GG 200 MM Hot Feed Rubber Extruder

TEMPERATURE CONTROL: Standard offers are with manual temperature control with valve opening/closing, whereas as in case of accurate temperature control requirement high pressure close loop thermo-fluid circuits with Electrical Heaters & pumps can be offered to control the temperature in ±1oC

ACCESSORIES: (OPTIONAL) Talcum unit, Post Extrusion Conveyors, Roller Die Head Units, Spray Coolers, Strip Winders, Blank storing Circular trays can be offered at extra cost.

FEATURES of Hot feed rubber extruder: