Company Information

Ask for more detail from the seller

Contact SupplierDescription

A. Applied range: DRT1100 Hot Melt Coating Machine Suitable for fabric compound production。

B. Technical parameters:

1. Coating method: Carving roll transfer coating (hot melt glue is coated on rollers with dot, then transferred to material)

2. Max. available coating width: 1300mm

3. Coating quality: 10-50g/m2(The amount of glue applied depends on the carving state of the carving roll.)

4. Max. line speed: 50m/min

5. Length of all roller surface: 1400mm

6. Max. rewinding diameter:600-800 mm (depends on your coating weight)

7. Max. unwinding diameter: 1000mm

8. Unwinding equipment: 2 set

9. Rewinding equipment: 1 set

10. RP120 hot melt sprayer: 1 set ,

11. Melt glue speed: 120kg/h (EVA.3000 centipoise 165℃)

12. Length of glue-carrying pipe: 4m (1 piece)

13. Temperature: 230℃

14. Power: app. 40KW

15. Power supply: ~415V±15% 50Hz

16. The quantity of glue can be adjusted independently or synchronously with the main machine

17. Oil temperature heater 24KW 1set

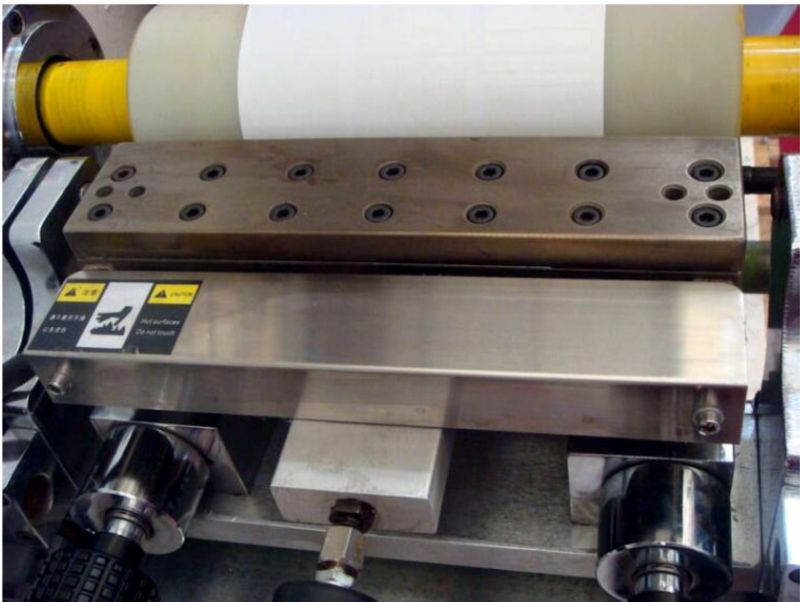

C. Main working parts

a) Machine rack

b) First and second unwinding part

c) Rewinding part

d) Glue melt tank(RP120)

e) Coating, laminating & roller part