Company Information

Ask for more detail from the seller

Contact SupplierRA Power Solutions is having experience of more than 44 years in the field of extending Crankshaft and Cylindrical Shaft repair services all over the world.

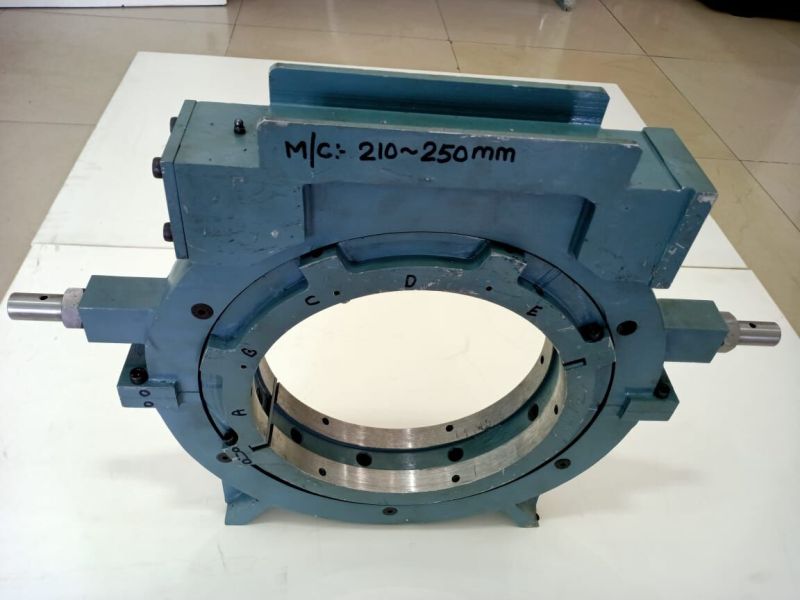

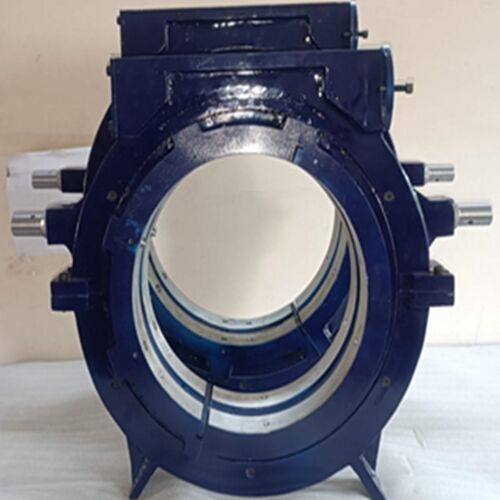

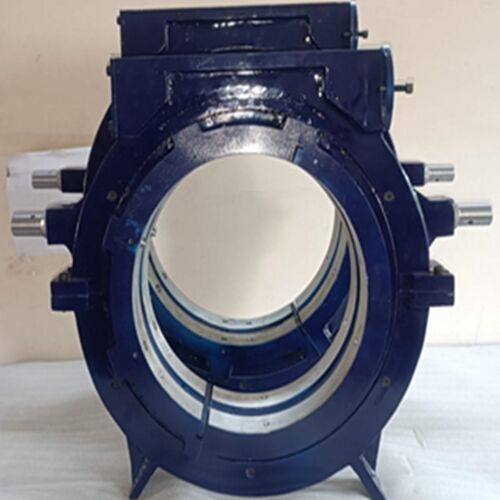

We also design, manufacture and supply In-Situ Crankshaft and cylindrical shaft repair machines up to 700 MM diameter.

The main advantage of In-Situ Crankshaft/Cylindrical Shaft repair machine is that there is no requirement for removal of Crankshaft, Intermediate shaft, Pump Shaft, or any type of Cylindrical Shaft from the casing. The grinding and repairs of damage shaft is possible On-Site.

Crankshaft Repair & Crankshaft Grinding by In-Situ Crankshaft Grinding Machine

Crankshaft Repair does not require the crankshaft to be removed from entablature. In the recent past due to seizure of bearing or development of taper, ovality, or loss of alignment of crankshaft, it was necessary to remove the crankshaft from the engine block and send it to the designated workshop for crankshaft grinding and crankshaft repair.

The introduction of a lightweight, vibration-free crankshaft grinding equipment facilitates grinding of crankshaft, crank pin, and crank main journal on the spot while the crankshaft is assembled in the engine block. There is no necessity of even decoupling the alternator and other accessories from the diesel engine.

Training In Situ Crankshaft Grinding Machine

We offer training to customer technicians in their workshop. The technicians should have basic knowledge and experience of handling common instruments like micrometer, bore gauge, and vernier caliper. The following areas are covered during the training of working on crankshaft grinding machine.