Listing ID #5877142

Company Information

Ask for more detail from the seller

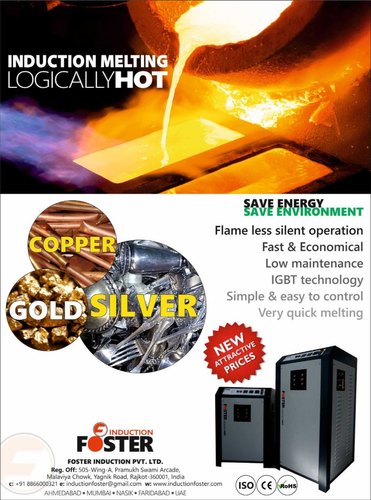

Contact SupplierFurnace for Copper Copper is a transitional metal, which means that it is a good conductor of electricity and heat. This makes it particularly valuable for construction, wire, piping and many other commonly used items. It is easily melted down to form whatever shape the user needs. There is not one single type of copper melting furnace for foundries, just as there is not only one process that can be used to melt copper. From cathode shaft furnaces for the continuous production of copper wire to gas fired reverberated furnaces for scrap copper melting and refining, manufacturing plants have a lot of options when it comes to melting and refining copper. Here are some of the reasons why induction furnaces ideal for melting of copper: Power RegimesInduction melting furnaces tend to be more flexible when it comes to alloying. These furnaces can be easily shut off any time the plant or factory closes, and relining is fairly quick and simple. They also tend to be more economical in terms of energy consumption, and they usually have a longer refractory lifetime. In the Induction furnace melting rate is very fast and large quantity of the metal can melt very quickly. ReliabilityWhen it comes to melting copper, a copper furnace based on induction is far more reliable than most others. Due to latest IGBT technology and standard built up the maintenance of furnace is almost nil, manufacturers can get the most out of this type of furnace without the need for any repairs. CleanlinessIt's well known that induction furnaces emit far less pollutants than other types of furnaces. Not only does this mean that you are protecting your employees from breathing in harmful substances, but having a clean atmosphere will also prevent any additional oxidation of the copper. Energy EfficiencyA recent study noted that today's modern induction furnaces can achieve higher electrical efficiency levels. That means less of a negative impact on the environment, and it means you won't be wasting more on energy costs.

Foster Induction Pvt Ltd

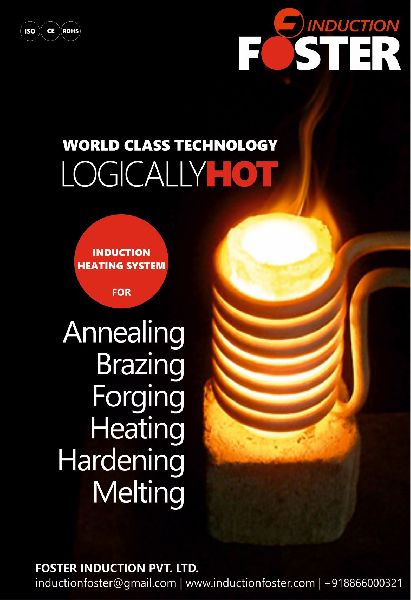

Being blest with state-of-the-art machines and deft professionals, Foster Induction Pvt. Ltd. has emerged as a remarkable manufacturer and exporter of induction brazing machine, induction heating machine, induction hardening machine, and melting furnace. Our organization is established in Rajkot, Gujarat and is pursuing its operations under the right guidance of Mr. Jignesh Patel since 2017.

Foster Induction Pvt. Ltd. makes use of the best quality basic input and produces the finished products under a hygienic environment with the aid of utmost sophisticated techniques. Our offered products are tested on various parameters to ensure the presence of zero defects.

Logistic team

Our logistic team renders us capable of making deliveries to far-flung clients on a timely basis. We are facilitated with enough commercial vehicles of all sizes to furnish small, medium, and bulk market requirements effortlessly. We strive to maximize the client satisfaction level by catering to their customized delivery requirements.

Packaging team

Our adroit professionals make sure that each and every product is packed in tamperproof packaging to avoid the chances of pilferage and spoilage. The A-grade packaging material used by us ensures that the quality remains intact and there is no influence of sunlight or external factors on the product. We offer our comprehensive range in different configurations to satiate the preference of our revered clients.