Company Information

Ask for more detail from the seller

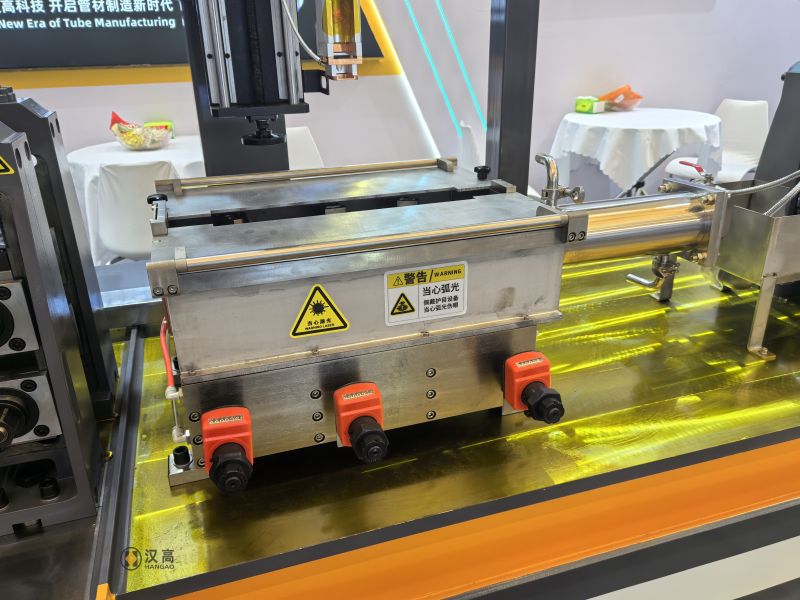

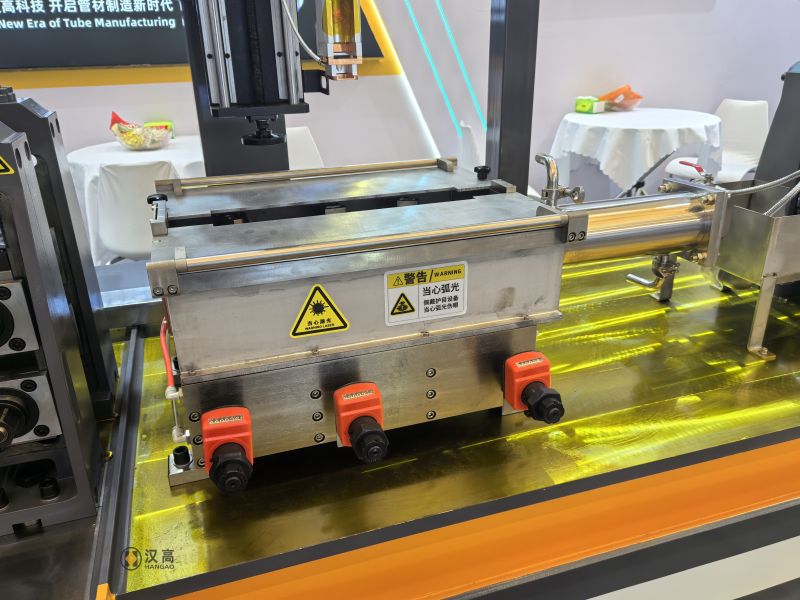

Contact SupplierHigh-Performance Industrial Pipe Welding Production Line

Our production line adopts W-type forming technology combined with an advanced three-cathode + dual electromagnetic control welding system. By simply changing roll molds, it can efficiently produce pipes in a wide range of specifications to meet diverse industrial needs.

Key Advantages:

Exceptional Precision

Shaft runout ≤ 0.02 mm guarantees superior dimensional accuracy and long-term operational stability.

High-Speed & Reliable Welding

Designed for efficiency while ensuring weld seams fully comply with ASME standards.

Outstanding Yield Rate

Consistently achieves a material yield rate of over 97%, reducing waste and maximizing profitability.

Comprehensive Data Traceability

Welding current, solution power, frequency, and other parameters are recorded in real time, ensuring every tube can be traced with complete accuracy.

Smart & User-Friendly Operation

Equipped with one-click preparation, start/stop control, automated data acquisition, process parameter storage and selection, and flexible adjustment across all process stages.

Built-In Safety & Monitoring

Features include perforation alarm protection and an integrated IoT monitoring system for remote supervision and predictive maintenance.

This production line represents a new generation of intelligent, high-precision, and reliable solutions for industrial pipe manufacturing, helping companies achieve higher productivity and lower operating costs.