Company Information

Ask for more detail from the seller

Contact Supplier

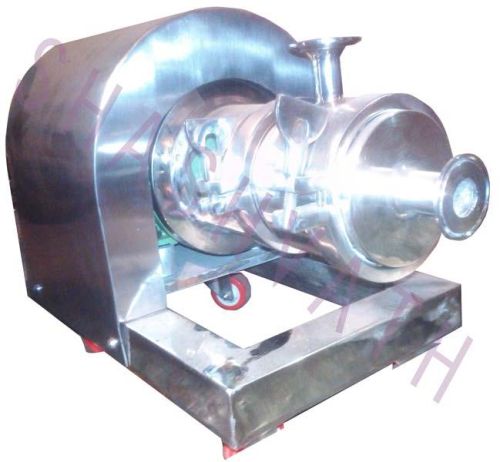

In Inline agitation system, the possibility of materials –Liquid or Solid passing through it, without subjected to intense hydraulic and mechanical shear actions is zero. Here suction pipe (inlet pipe) is centrally mounted & outlet is radially mounted , therefore it is physically impossible for any material to pass from inlet to outlet without exposed to agitation.

The homogenizer is often necessary to mix one or more substances within a liquid. This device allows to micronize and scatters the particles suspended in the fluid, so that the product become highly stable, no matter the followings treatments and stockings the products may undergo. The homogenizer delivers unparalleled consistency and control of high shear process applications such as, Immiscible Phase Emulsifying, Homogenizing, Wet Grinding, Texturing, Deagglomeration and Fine Dispersing.

The stator which surrounds rotor is available with various type of opening i.e. round, square, rectangular & with perforation also so that all the critical demand of Mixing, Emulsifying, Disintegration & Dispersion of solids, suspension can be met out by same equipment.

FEATURES :

Design is cGMP with all contact parts AISI 316.

Capacity up to 5,000 liters.

Single-pass processing results in reduced batch times by up to 80% and repeatability batch-after-batch

Energy savings when compared with in-tank mixers, colloid mills and homogenizers.

Increased capacity when compared with colloid mills and homogenizers

Improved product quality and shelf-life stability.

High Differential Velocities.

Rotar and Stator type.

Trolley mounted, with PU Wheels and support for easy handeling.

Different type of stator (Coarse/Medium/Fine) for specific Particle size reduction.

Variable Frequency can also be provided.

Types of Homogenizer :

SINGLE STAGE

DOUBLE STAGE

FOUR STAGE

APPLICATION

Pharmaceuticlas – Making of Medicinal Formulation ,Suspension ,Syrup ,Ointment Etc.

Food Industry : Making Purees, Pastes, Granulation etc.

Cosmetic Industry : Making Creams,Suspension Etc.

Bio-Technology – Making of Granulation ,Suspension ,Colloidal Solution Etc.