Company Information

Ask for more detail from the seller

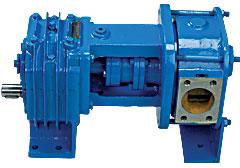

Contact SupplierThe very first pump produced by Delta Group in 1968 was an Internal Gear Pump Model DIG-10 for low-pressure burner service - till this day it is in production with great success. Subsequently Delta Group had the foresight to introduce several other designs, to take care of growing industrial demands, thus placing themselves on the forefront in the field of Rotary Positive Displacement Pumps.

Experience gained over years in designing and building Rotary Pumps combined with knowledge in Application Engineering has resulted in this development of New Stainless Steel Internal Gear Series specifically for food, chemical and pharmaceutical industry.

Innovation, simple construction has ensured very easy maintenance and totally reliable hassle free installation.

Working Principle

Delta DIG series employs proven Internal Gearing (Gear within Gear) principle for pumping. The main gear is keyed to the drive shaft, and rotates concentric in the pump casing. Idler is located on an eccentric pin on the front cover to rotate freely and meshes with main gear when assembled. A crescent shaped partition precision machined on the front cover maintains a small, but positive clearance to achieve perfect scaling between parts. As the gears come out of mesh, a partial vacuum is created, forcing the fluid to rush into the pump casing and fill in the voids between the teeth. Both gears rotating in the same direction of rotation gently transfer the fluid to the delivery port. The resulting action is a smooth-steady flow; low in pulsation, noise and vibration.

Single shaft design well supported on outboard bearing (except for one inside sleeve bearing) enables to pump products even with poor lubricating value unlike in the external gear pumps. External bearing construction offers easy access the pump components i.e., rotor set and even pump casing simply by removing the front cover without disturbing drive parts, bearings etc., and in place. Block pump mounted integrally on hollow shaft gearbox automatically reduces the speed (in several ratios) and enables even the pump rotor to be pulled out without disturbing the drive! It is easily possible to jacket front and rear covers for products heating - thus making the design unique and versatile - ideally suited for process pumping.

Salient Features

Smooth quite flow Reversibility

Excellent self priming Bracket/ Gear box mounting allows free expansion/ contraction - alignment not affected

Insensitive to viscosities Easy maintenance

All metal construction, no contamination Built-in reducer offers ideal speed range 240~960 RPM

Single sealing, external bearing Slow speeds ensure better pumping & longer life

Low noise and pulsation Reduced maintenance

Construction

The DIG series is modular developed with excellent interchangeability. The pump is available either as bracket mounted 'BM' or gearbox mounted 'GM" models. The bracket mounted casing construction provides stress free operation while handling products at higher temperatures. The major components are casing, front cover, rear cover, seal box (casing parts) and rotor set (rotor, idler and shaft). Most casing components are made by lost wax process for better finish and grain structure.

'GM' version offers a choice of different speed ratios, making it easy to handle viscous products besides eliminating problems of alignment, extra set of coupling. Standard 4 pole or 6 pole motors can be directly coupled to such units making it very reliable, compact and clean drive. Another unique feature is the adjusting clearance between rotor set and cover by means of rotor positioning device enabling to restore pump capacity even after wear and tear after a long use.

Pumps can be equipped with Heating/ Cooling Jacket on front cover/ rear cover and in some cases also Pump Housing. Choice of Mechanical Seal/ Stuffing box is available for shaft sealing.

Typical Parameters

Capacity upto 800 LPM

Pressure upto 14 kg/cm2

Viscosity upto 100,000 cSt

Temperature upto 200°C

Baby Foods | Fruit Concentrates | Lecithin | Soap |

Batter | Fruit Drinks | Lotions | Soups |

Butter | Fruit Fillings | Margarine | Starch |

Caramel | Fruit Puree | Mayonnaise | Sweeteners |

Chewing Gum Base | Fudge | Molasses | Syrups |

Chocolate | Gelatin | Oils | Soft Drink Concentrate |

Coffee | Glucose | Peanut Butter | Tomato Puree |

Cookie Dough | Gums | Printing Ink | Tomato Paste |

Cottage Cheese | Honey | Pudding | Tooth Paste |

Curd | Ice Cream | Putty | Wheat Gluten |

Extracts Flavoring | Icing | Red Chilly Paste | Whey |

Fondant | Jams | Salad Dressings | Yeast |

Fats | Jellies | Sauce | Yeast Slurry |

Frostings | Ketchup | Shampoos | Yogurt |