Company Information

Ask for more detail from the seller

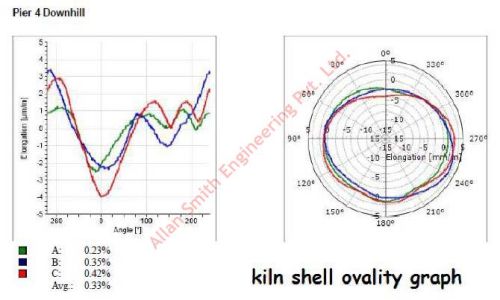

Contact SupplierKiln Shell Ovality Measurement and Analysis is a diagnostic procedure conducted to assess the degree of deformation or out-of-roundness in the kiln shell during rotation. This measurement is typically performed using a portable ovality sensor or beam deflection gauge mounted on the kiln shell near the tyre. The analysis determines the dynamic movement of the shell in both loaded and unloaded conditions, with the ovality value expressed as a percentage of shell diameter (typically ranging from 0.03% to 0.15%). Data is collected over several revolutions and processed to identify excessive flexing, tyre migration, flat spots, or mechanical misalignment. The test is conducted while the kiln is in full operation and helps detect shell fatigue, refractory damage risk, and mechanical imbalances. Ideal ovality levels vary with shell diameter and thickness, but any deviation beyond standard tolerance limits requires realignment or corrective grinding. The service is essential for preventive maintenance and to ensure the kiln’s structural integrity and operational reliability.