Company Information

Ask for more detail from the seller

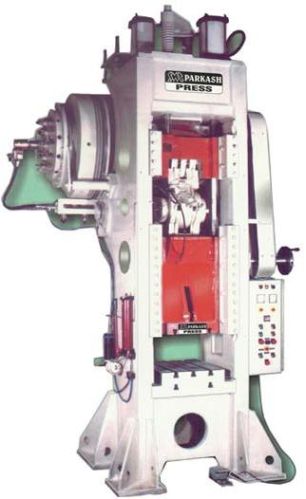

Contact SupplierFrom India, we are offering Knuckle Joint Presses that are manufactured with perfection and widely reckoned for their excellence. The offered Presses are widely used for manufacturing products and can also be equipped with automatic devices to facilitate material handling and speedy production. One can also get them in tailored specifications, from us. Approach us for price quotes and placing orders.

Knuckle Joint Leverage Details :

Frame : Consist of two or several members assembled by tie bars made of special steel and shrunk in position.

Crankshaft : Forged from solid billet is machined and ground all over and runs in two bronze bearing which is well lubricant from centralized system.

Clutch & Brake : Low inertia multidisc clutch and brake is used for transmitting power to the machine. Wear adjustment is compensated by little additional movement of inbuilt air cylinder.

Counter Balance : Slides are counter balanced by pneumatic cylinders to eliminate any possibility of its running ahead of specified speed and also to counteract possibility of rebound due to bottom ejector.

Safety : All presses are equipped with pneumatically operated safety controls with provision of single and continuous stroking, inching and two hand operation.

Standards with Machine :

| Model No. | PKC-100 | PCK 160 | PCK 250 | PCK 400 | PCK 600 | PCK 800 | PCK 1000 | |

|---|---|---|---|---|---|---|---|---|

| Frame Type | Unit frame | Unit frame | Unit frame | Unit frame | Unit frame | Unit frame | Unit frame | |

| Running Type | Gear Running | Gear Running | Gear Running | Gear Running | Gear Running | Gear Running | Gear Running | |

| Capacity | Ton | 100 | 160 | 250 | 400 | 600 | 800 | 1000 |

| Slide Stroke Standard) | mm | 70 | 100 | 120 | 140 | 140 | 150 | 150 |

| Number of Stroke (Standard) | S.P.M. | 60 | 50 | 40 | 40 | 35 | 30 | 30 |

| Adjustment Of Slide | mm | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Shut Height | mm | 300 | 350 | 370 | 400 | 400 | 450 | 450 |

| Thickness Of Bolster | mm | 75 | 75 | 100 | 120 | 120 | 150 | 150 |

| Area Of Bolster | mm | 400x450 | 450x500 | 500x600 | 550x650 | 600x700 | 650x800 | 750x950 |

| Area of Slide | mm | 300x300 | 320x320 | 350x400 | 400x500 | 450x550 | 450x550 | 550x650 |

| Main Driving Motor | kw | 5.5 | 7.8 | 11 | 15 | 22 | 37 | 45 |

| Slide Adjustment Motor | kw | Hand operation | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |