- Supply TypeManufacturer, Exporter, Supplier, Retailer

- Preferred Buyer Location All over the world

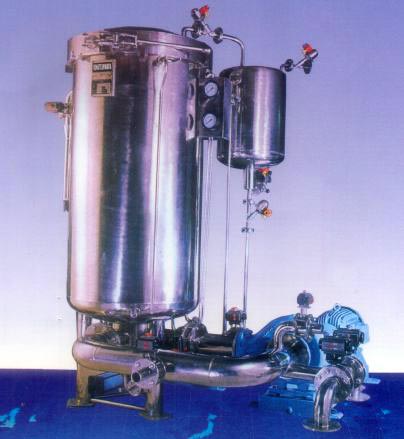

We are a prominent Laboratory Sample Dyeing Machine Manufacturer, Exporter and Supplier. We are engaged in making available feature packed Laboratory Sample Dyeing Machine. Made from to quality....

View More Details