Company Information

Ask for more detail from the seller

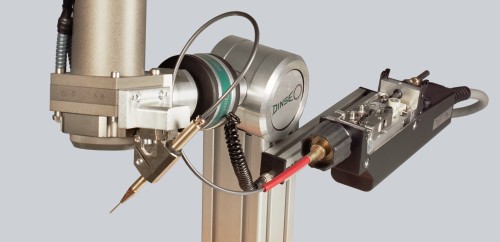

Contact SupplierLaser-welding and -brazing allows the maximum of production reliability for sophisticated processes. The use of filler wire offers key technological advantages: ideal material alloy, prevention of hot cracks during aluminium welding, reduced process temperatures, high tolerance compatibility as well as a high process speed. For this reason DINSE has been developing and optimizing these systems for decades. The key to success is the combination of technological research and development and practical relevance. DINSE has focused especially upon the further development of wire feeding and wire monitoring. In DINSE laser systems the PUSH-PUSH technology comes with two fully-uncoupled drive units. The speed controlled front-drive feeds the demand-actuated quantity of wire; the adjustable torque of the rear-drive limits the feed force. This ensures a constant wire feed regardless of length, bend and torsion of the torch set.

A newly developed drive system with four roles allows precise feeding and positioning of the wire due to idealized force transmission. The wire feed is thereby optimized, slipping of the drive roller is minimized. Close to the process, behind the motor a digital sensor controls the wire feed and collects data for a comprehensive monitoring of the process. At the monitoring the sensor-based, highly precise wire positioning and feeding with measurement of distance and the adjustment of the exact quantity of the weld deposit are automatically documented.