Company Information

Ask for more detail from the seller

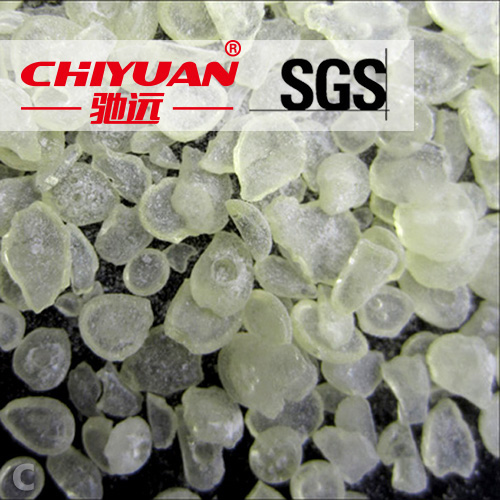

Contact SupplierC9 Cold Polymer Petroleum Resin

C9 cold polymer petroleum resin refer to the resin material which includes nine carbon atoms "olefins or ring olefin polymerization or with aldehydes, aromatic hydrocarbons, terpene compounds such as copolymerization and become".

1. Coating: petroleum resin can be blended with various drying oil to produce paint, adding various kinds of resin and pigment to obtain all sorts of color coating which are widely used in the surface coating of vehicles, ships and bridges. Greatly improved the paint film’s gloss, hardness, water resistance, alkali resistance and reduce the production cost.

2. Rubber : petroleum resin is suitable for being the additive of synthetic rubber. It can improve the forming operation, increase the hardness and elasticity of the product. Due to the strength and aging resistance of the improved rubber, this kind of resin is particularly suited to be softener of SBR rubber and used in the production of rubber hose, triangle and tires.

3. Adhesive: petroleum resin has good cohesiveness. It is preferable tackifier in adhesive and pressure-sensitive adhesive tape. Used in the production of plywood, wall paper and leather with adhesive to improve the water resistance of the adhesive. Because of its solidification shrinkage small, can be applied to the casting industry.

4. Ink: petroleum resin has many performance, such as water resistance, refractory consumption and dry resistance. Adding petroleum resin in printing ink has many effect such as showing color, fast drying, blasting and improve printing performance, so that it can produce all kinds of printing ink.

Production Parameter:

Item Specification Color Softening Point℃

A B

C9C-110AB 5-8 4-8 110

C9C-120AB 5-8 4-8 120

C9C-130AB 5-8 4-8 130

C9C-140AB 5-8 4-8 140

C9C-150A 5-8 4-8 150