Company Information

Ask for more detail from the seller

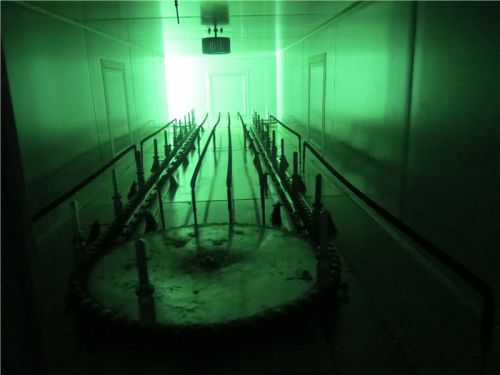

Contact SupplierUV spray line for plastic and vehicle paint spray and baking.Cabinet System Wall panel 50mm thick rock wool with 0.6mm colorful steel coating; External and interior surface were coated with transparent anti-static coating. All panels are equipped with electrical connectors. Roof 4PCS stainless steel bracket frame, high-quality filter cloth. Galvanized plate roof. Basement Galvanized steel sheet construction, two rows grid plate& three flower pattern plate, outside two pieces 620mm*2000mm ramps. Ventilation System ,Air inlet system: One 7.5kw motor with direct connection fan, The air damper uses "ARTAC " brand pneumatic air server, 25000m3h Air discharge system: One 5.5kw motor direct drive, 3m straight duct, 1m elbow duct Heating System: Burner Italian Riello Burner G10UV Spray Line Workflow (Reference): Load -> Manual Dust -> Primer Spray -> Flash -> Curing -> Topcoat Spray -> Infrared Flattening -> Curing -> Cooling -> Unloading Detailed workflowPrimer: On-line Electrostatic Cleaning Primer Loading Products - Infrared Flat UV Curing - Cooling - Dehydration LineVacuum coating: load products in the evaporative vacuum coating machine - metallized unloading productsTop paint: UV products on the product - electrostatic cleaning top paint - infrared leveling preheat - UV curing - cooling - unloading products. Spray booth Size:3.0*2.5*2.2m Stainless steel machine bodyStainless steel water tank Explosion