Company Information

Ask for more detail from the seller

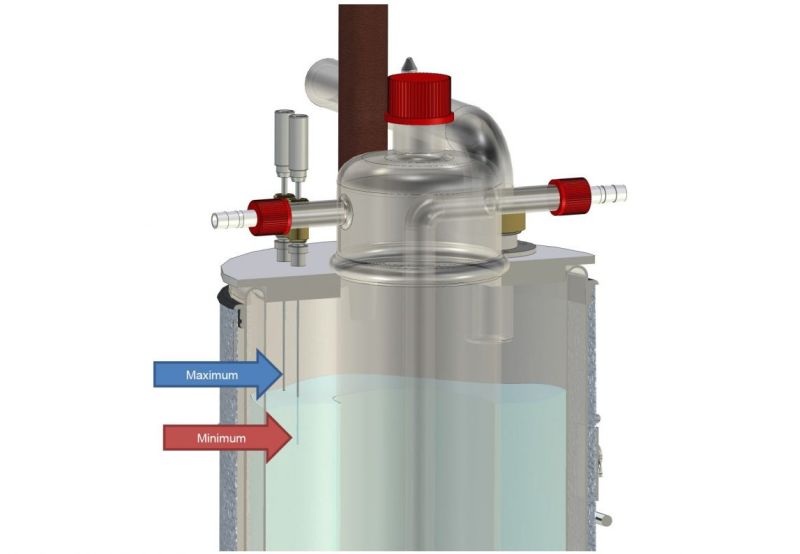

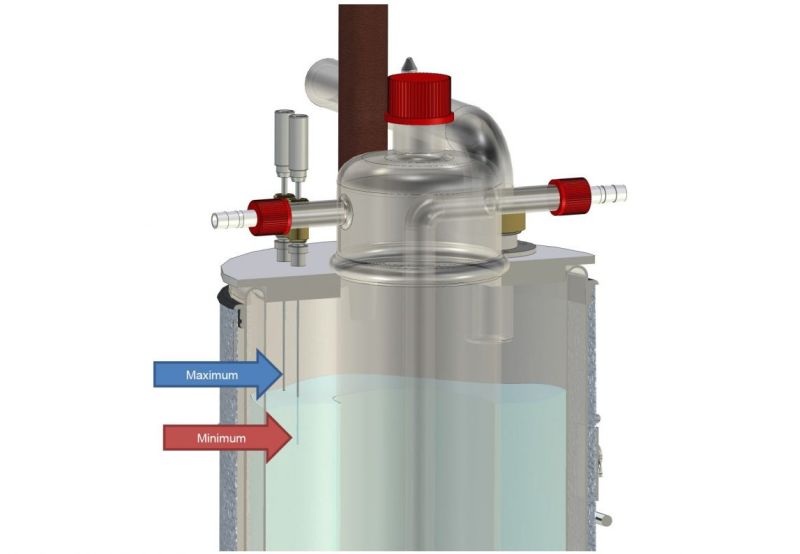

Contact SupplierIn many cryogenic applications, such as shrinking shafts and bushings in LN2, deep-freezing components or biological samples, using LN2 as a coolant in cold traps, calibrating sensors in LN2, etc., it is important to maintain a constant LN2 liquid level. This can be achieved with the LN2 Level Control. With this LN2 Level Controller, the LN2 level can be set between a minimum and a maximum sensor and kept constant. This LN2 Level Control can be connected to almost any LN2 tank.

If the LN2 level falls below the minimum sensor, a signal is sent to the level controller. The level controller then opens a 24 volt LN2 solenoid valve, which is connected to the removal siphon of the LN2 storage container. The excess pressure in the LN2 storage tank forces the LN2 out of the tank and through a transfer line to the working dewar vessel. The LN2 flowing into the working dewar vessel raises the liquid level until the maximum sensor is immersed in the LN2. This cools down the maximum sensor and sends a signal to the level controller. This then de-energizes the solenoid valve so that it closes and interrupts the LN2 supply. If the LN2 level has fallen below the minimum sensor again after some time, the process described above is repeated.