Listing ID #6888038

Company Information

Ask for more detail from the seller

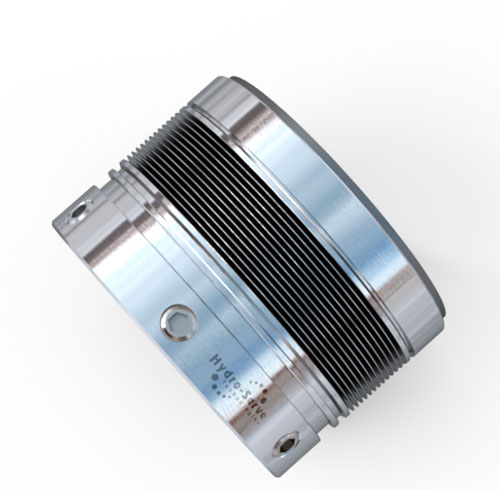

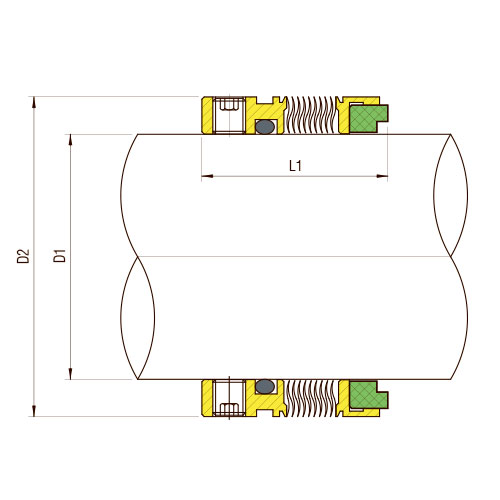

Contact SupplierThe MB1 metal bellow seals are widely utilized in applications involving moderate temperature oils and hydrocarbons. These seals offer several advantages in such environments. One notable feature of the MB1 seal is its high degree of axial flexibility, which allows it to compensate for shaft misalignment or lack of concentricity. This flexibility enables the seal to maintain effective sealing performance even in situations where the shaft undergoes thrust movement.

Additionally, the MB1 seals are particularly well-suited for high-temperature applications commonly found in industries such as refineries, petrochemical plants, and the oil and gas sector. The seals are designed to withstand the extreme temperatures typically encountered in these environments. This makes them a reliable sealing solution for processes involving hot oils, hydrocarbons, and other high-temperature fluids.

An important advantage of the MB1 seals is that they do not incorporate dynamic O-rings. This design choice eliminates the issue of fretting, which refers to the damage caused by the repeated movement or rubbing of a dynamic O-ring against the shaft or sleeve. By eliminating dynamic O-rings, the MB1 seals minimize the potential for fretting and extend the service life of the sealing system

Salient features:

Applications:

Material:

Operating Parameters:

We, Hydro Serve Technologies are a leading manufacturer and supplier of highly engineered mechanical shaft seals and components. We specialize in the design, manufacture, and supply of a wide range of mechanical seals and components used in various industries such as oil and gas, chemical, power, and water.

Our mechanical seals and components are designed to withstand the toughest conditions and are made from the finest materials to ensure their durability and longevity.

Our team

We have a team of experienced engineers who work closely with our customers to understand their requirements and develop products that meet their needs. Our engineers use the latest software and design tools to develop products that are efficient, reliable, and cost-effective.

Our infrastructure

We have a state-of-the-art manufacturing facility that is equipped with the latest machinery and equipment. We have strict quality control measures in place to ensure that our products meet the highest quality standards. Our quality control laboratory is equipped with the latest testing equipment to ensure that our products are tested rigorously before they are shipped to our customers.

Our distribution network

We have a well-established distribution network that enables us to deliver our products to customers across the country. Our distribution centers are strategically located, and our fleet of vehicles is equipped to handle large quantities of products, ensuring timely delivery to our customers.