Listing ID #4940699

Company Information

Ask for more detail from the seller

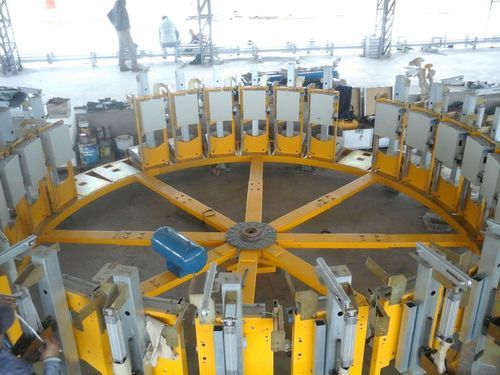

Contact Suppliersonmez makina carrousel filling system is designed for safe and effective filling of all kinds of lpg cylinders.

type: automatic and manual as per customer requirement

capacity: 800 cylinder to 3600 cyl/hr

filling point : 6 to 36 filling head

cylinder handling : design for all size cylinder

• the most effective way of filling lpg cylinders

• high capacity filling, up to 1,800 cylinders per hour

• fully automatic cylinder flow

• high safety level thanks to intrinsically safe network

• decentralized control units independent of pc’s

• rapid encoding or automatic reading of cylinder tare

• control system uptime: 99% – the best on the market

• total overview of the filling production thanks to pc data collection

equipment in hazardous area:

1 chain conveyor

2 encoding station

3 introduction and ejection units

4 filling carrousel and filling machines

5 check scale

6 sort-out conveyor

7 leak detector

8 power and data interface

equipment in non-hazardous area:

a pc incl. Software and database for filling data

b modem for connection to smipl on-line service c printer for printing reports

your possibilities :

• semi-automatic or fully automatic system according to valve type

• automation level can be upgraded according to actual and future needs

• from 6 to 36 filling machines on the carrousel platform – capacity can be adapted to actual and future needs

• filling machines and filling heads adapted to cylinders and cylinder valves

• pc placed in non-hazardous area can be connected to the system

• quick and professional service backup by remote control available

your benefits:

• low installation costs and high safety thanks to intrinsically safe network

• focus on ergonomics at central tare encoding station

• few operators and minimized risk of human errors

• no mechanical wear on electrical control equipment, non-touch sensors and swivel connectors

• optimal logistics and high output (e.g. Sorting of cylinders for maintenance before filling)

• optimal pc data collection tool for effective filling and maintenance

• capacity increase is possible

• same user interface (hmi/cuc controller) on all machines

your safety:

• ex marking according to the atex and peso directive and applicable en standards: ii 2g ex h iib t3 gb

• all equipment and machines in the filling system are intended for operation in hazardous areas classified as zone 1 or zone 2 according to en/iec 60079-10-1

• all equipment and machines in the filling system are designed and validated in accordance with a certified iso:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable eu directives

• filling machines and check scales have weighing accuracy classification c3 according to oiml r 76/en45501

SONMEZ MAKINA in-line filling systems are designed for safe and efficient filling and checking of all kinds of LPG cylinders.

• Suitable system for low capacity filling of industrial cylinders

• Capacity between 50 and 250 cylinders per hour

• Semi-automatic handling of cylinders

• Flexible to different cylinder diameters, heights and cylinder valves

• Filling machines can perform both filling and check weighing

• Flexible solutions – with possibilities of expansion

• Small investment

Your benefits:

• Low installation costs

• High safety thanks to intrinsically safe network

• Focus on ergonomics

• Minimum manual cylinder handling

• Includes automatics for regulation of cylinder flow

• Controlled cylinder logistics

• Ready for communication with PC for data collection

• Capacity increase is possible

Your possibilities :

• Manual or semi-automatic filling head according to valve type

• Parallel filling lines for increased capacity

• 1 to 8 filling machines per filling line

• Weighing principle or mass flow principle

• Can be integrated in chain conveyor or roller conveyor

• Manual or semi-automatic handling of cylinders

• Filling of both domestic and industrial cylinders

• Automation level can be upgraded according to actual and future needs

Your safety:

• Ex marking according to the ATEX Directive and applicable EN standards: II 2G Ex h IIB T3 Gb

• All equipment and machines in the filling system are intended for operation in hazardous areas classified as Zone 1 or Zone 2 according to EN/IEC 60079-10-1

• All equipment and machines in the filling system are designed and validated in accordance with a certified ISO:9001 quality management system; furthermore, they are designed according to all relevant requirements set out in applicable EU Directives

• Filling machines and check scales have weighing Accuracy Classification C3 according to OIML R 76/ EN45501