Company Information

Ask for more detail from the seller

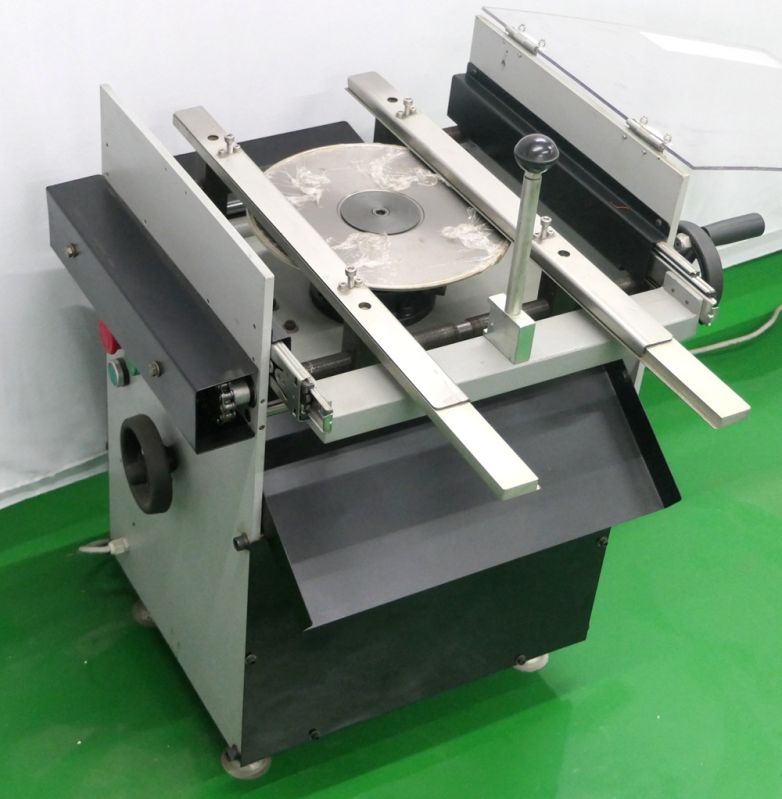

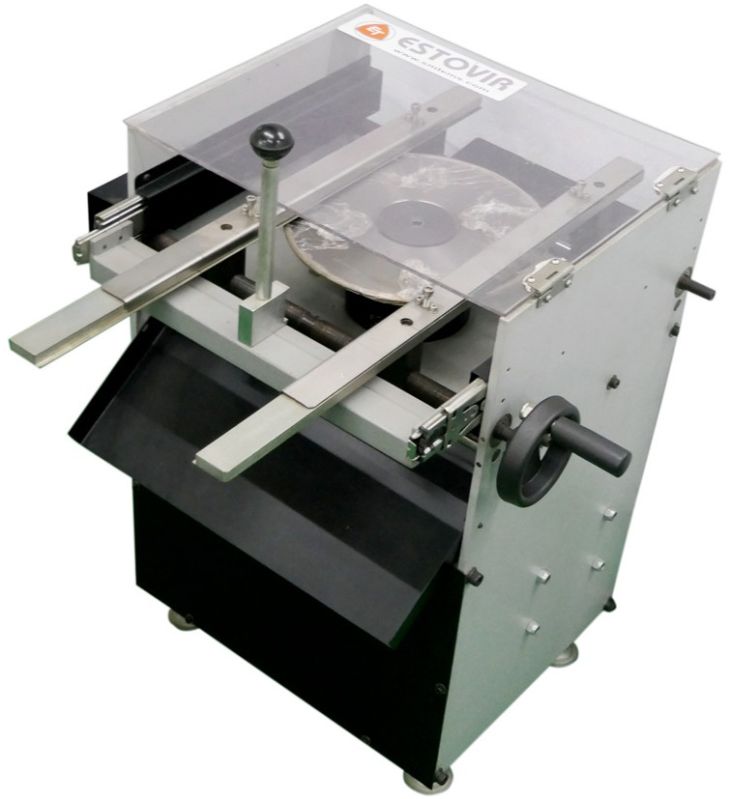

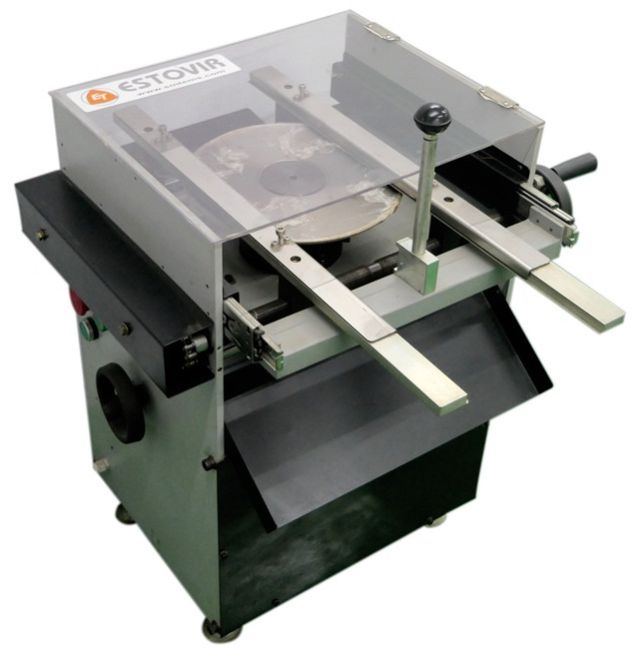

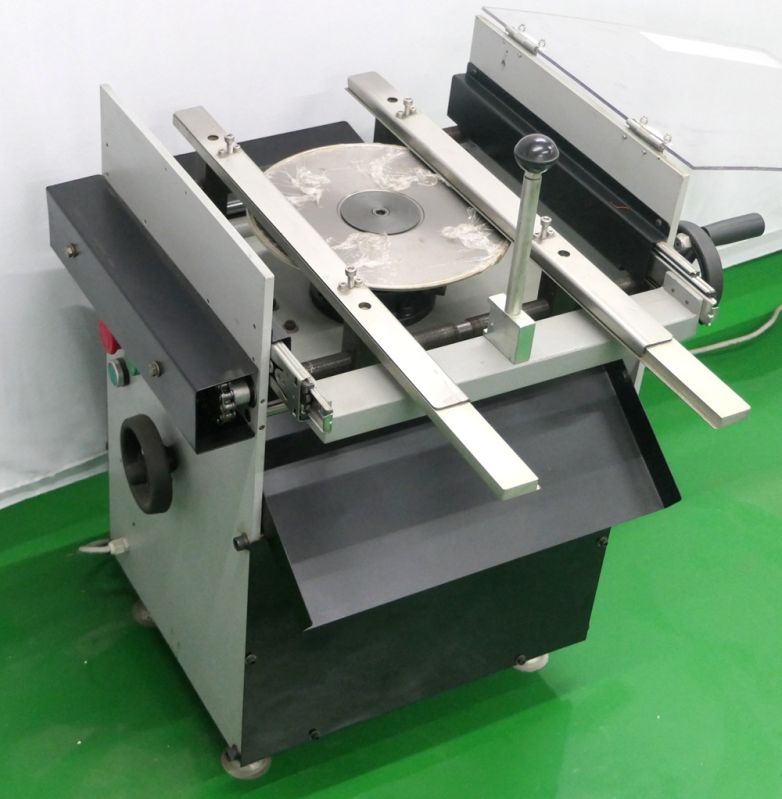

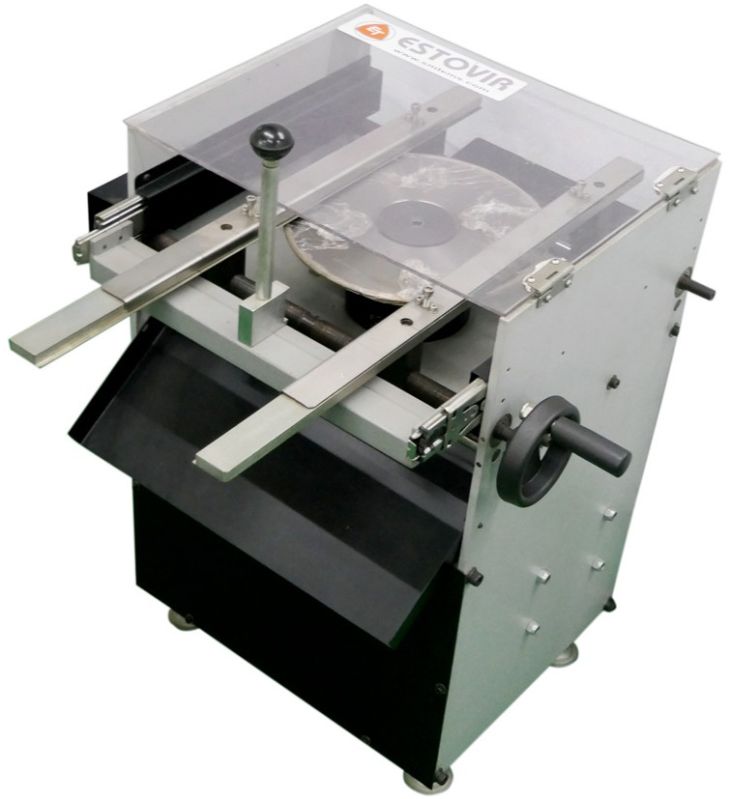

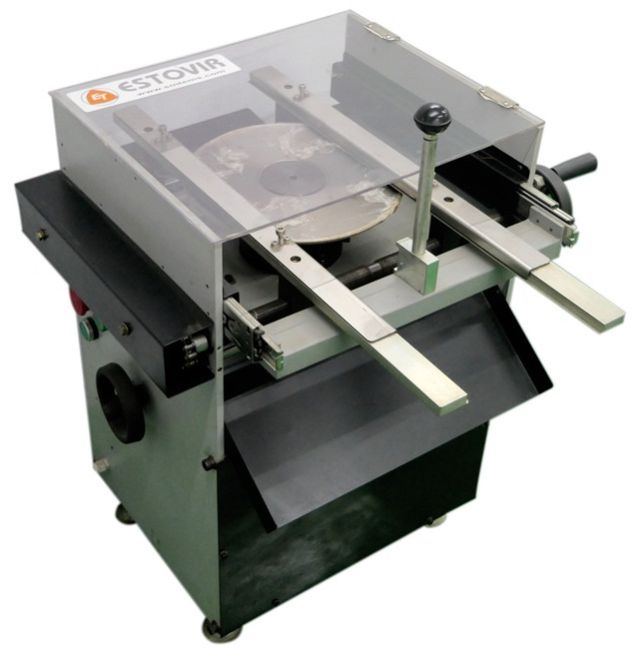

Contact SupplierAutomatic PCB Lead Cutting Machine – LC A66

The LC A66 Automatic PCB Lead Cutting Machine by Estovir Technologies is engineered for post-solder lead trimming in high-volume PCB assembly lines. Using a conveyor chain mechanism, the machine automatically clamps and transports PCBs towards a high-speed tungsten carbide blade (LC TC 250) for accurate and uniform lead cutting. Built with a wrap prevention device, it ensures damage-free processing, making it the perfect choice for electronics, consumer goods, and automotive PCB manufacturing. With a spindle speed of 4500 RPM and adjustable conveyor control, the LC A66 delivers unmatched speed, safety, and precision.

Specifications

Key Features of Automatic PCB Lead Cutting Machine LC A66

Why Choose LC A66?

Applications of Automatic PCB Lead Cutting Machine LC A66

Maintenance & Blade Information