Company Information

Ask for more detail from the seller

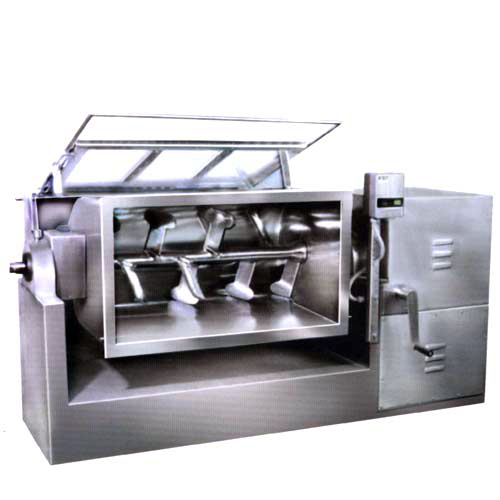

Contact SupplierMass Mixers offered by our organization are utilized for processing products such as tablets and powder, among others. The Mass Mixer machine is basically a mixing assembly wherein the mixing stirrer is in a horizontal position in the container and have a single speed, simple rotation. The stirrer rotates around it self at a very slow speed inside the bowl and thereby achieves intimate mixing of dry or wet material of tablet granulation, powder, chemicals and food & confectioneries. Owing to the special design of the machine and stirrer, the mass mixer can easily mix the sticky material. These machines can also uniformly and intimately mix material, which are too difficult to mix.

Features:

Optional: