Company Information

Ask for more detail from the seller

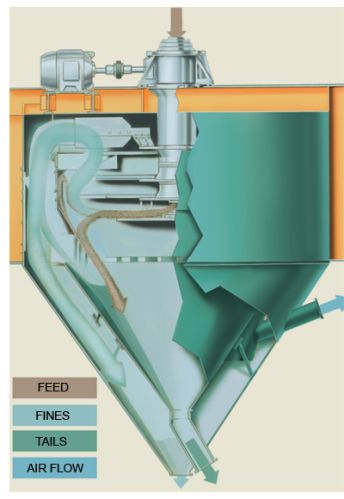

Contact SupplierBuilt in 11 commercial sizes ranging from 4 feet to 24 feet in diameter, as well as a 30 inch unit for small capacities and test run. a special 10 inch laboratory separator completes the Raymond line, and is a useful machine for handling small lots of materials in experimental works. on many material finished product with a high percentage passing 15 to 20 microns can be obtained without difficulty.

Advantages

Single whizzer separator

has one bank of whizzer blades and used for coarser separations upto approximately 85% to 90% passing 200 mesh

double whizzer separator

with two banks of whizzer blades,they can produce finished materials upto 99% to 99.5% passing 325 mesh.

Application in closed circuit grinding

When operated in closed circuit combination with pulverizer , ball or tube mills the separator skims off the fines rapidly so the mill works only on fresh material without wasting power. The tailings are discharged back to the mill for further reduction.the reground material is returned to the separator with the feed thus setting up a constant circulating load.