Company Information

Ask for more detail from the seller

Contact SupplierEngineered specifically for small diameter applications, the Mfml Turbine Ultrasonic Flow Sensor provides accurate readings in two flow ranges: 0.3 to 3.8 lpm and 3 to 38 lpm (0.1 to 1 gpm and 0.8 to 10 gpm). The injection-molded PVDF body and ceramic bearings provide excellent chemical compatibility and long service in dosing and batching applications. Union piping and tubing connections along with removable NEMA 4X electronics allow for easy assembly and field replacing ability. The mfml Ultrasonic Flow Sensor can be used with DN8 (¼ in.), DN10 (3/8 in.) DN15 (½ in.) tubing or DN15 (½ in.) piping for simple installation. End connections of the Ultrasonic Flow Sensor are available in PVDF for hose barbs, fusion socket or IR/butt fusion, and in PVC for socket or NPT thread.

Fields of Application -

Advantages -

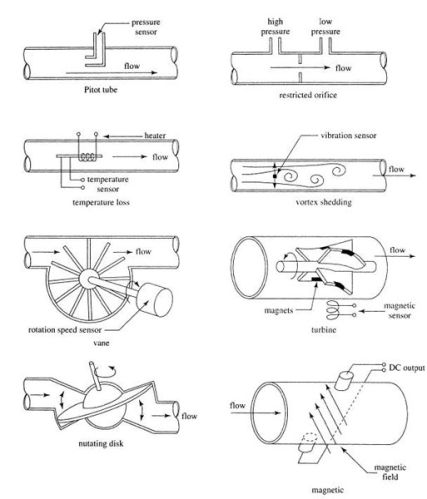

There are many different technologies used in the measurement of flow. The choice of the most suitable type depends on a wide range of factors including the nature and viscosity of the fluid, the flow rate range and the accuracy of measurement required.

Types Of Ultrasonic Flow Sensor -

Details -