Company Information

Ask for more detail from the seller

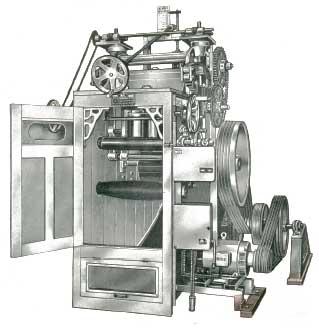

Contact SupplierWe offer Milling Machines, which translates into satisfaction at every level for you. these machines operate at high capacities with precision even under high stress conditions to ensure that production never gets affected. the categories of milling machines being provided by us include vertical and horizontal milling machines that can be used for a variety of purposes like flattening the surfaces of fabrics (especially woolens), shoulders, inclined surfaces, producing slots. the flawless performance of these machines has made us the leading manufacturer & supplier of milling machines.

features :

accurate performanceeasy to install & handleproduction capacity – 100 to 205 blanketshigh operational speedenergy efficienteasy to operatelow maintenance

| Electric Load | 20 H.P. (29 AM) 1440 R.P.M. |

|---|---|

| Width of the Machine | 6'-4" (1930 mm) |

| Length of the machine | 9'-4" (2845 mm) |

| Height of the machine | 10' ( 3050 mm) |

| Working space required | 15' X 50' |

| No. of V-Belts required | 9 Nos. Section C 154" to 156" |

| Speed of the main rollers | Between 110 to 120 R.P.M. |

| MAIN BODY: | Main Body is Fabricated from M. S. Channels lined with Aluminium sheets and 1p thick aeodar wood planks. Inside bottom is lined with 3 mm P.V.C. Sheet. |

|---|---|

| MILLING ROLLERS: | Two rollers 21" dia and 10" face are fitted in the machine. The rollers are made of 3" dia.60" long M.S. Shafts fitted with C. I. knobs mounted with seasoned shisham wood blocks. The upper roller shaft is fitted with brass housing and the lower roller shaft is mounted on Heavy Duty ball bearings for smooth running. Both rollers are chain driven, having chain gears and chain on both the sides for having equal revolutions, chain tightening arrangement and chain timing cam is provided with the machine. |

| BOX: MILLING | Cloth Milling Box is made of Heavy Duty C.I. Plates 42r'X10r' ½ lined with acid and alkali proof S.S. sheet or Rigid P.V.C. sheet or poly pick sheet, (or as required) press plate is fitted with bubbling spring arrangement and an indicator is provided to check up the pressure on the cloth while in process. Pressure of the press plate is controlled by hand according to the requirement in accordance with the quality of the cloth with hand wheel fitted in the front of the machine connected with the bubbling spring by shaft and beval gears. |

| DRIVE: | Main rollers are driven through counter shaft and V-Belt pulleys directly connected to' Electric Motor through dead load proof (for the safety of the Electic Motor) clucth and V-Belts. |

| Safety Roller: | One S. S. 4r' dia guide roller is mounted in the machine on bearings fitted with an automatic stop motion clutch. A limit switch is provided to stop the functioning of the electric motor when any knoughts are created. Two S. S. guide rollers 4. dia are fitted on bearings in front of the machine to increase or decrease the width of cloth which is operated by hand. |

| Pressi ng of Roller: | Pressure of the upper roller on the cloth can be increased or wheel connected to the heavy duty Kamani spring to worm and worm-gears. of taking a load of 5 Ton. |

| Feeding & Delivery: | The cloth is passed over two guide rollers into the Milling Box and both sewed to make it endless so that it may pass again and again from main rollar and in Rprocess. |

| General Description: | The machine is High Speed Italian Type, heavy duty, sturdy, smooth running production in short time. Very small quantity of chemicals used by Sprinkling mechanically through a funnel and perforated pipes. This machine is marked for evenness of goods, lusture and no fibre split off. |

| PRODUCTION: | 100 to 250 Blankets per shift according to the quality of cloth (approximate) |

| GROSS WEIGHT: | 30 Qtls. |