Listing ID #456904

Company Information

Ask for more detail from the seller

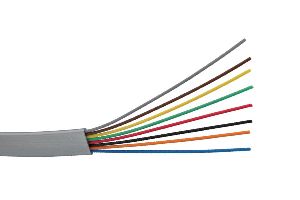

Contact SupplierWe are offering Mineral Insulated Copper Cable.

Mineral-insulated copper-clad cable is a variety of electrical cable made from copper conductors inside a copper sheath, insulated by inorganic magnesium oxide powder. The name is often abbreviated to micc or mi cable, and colloquially known as pyro (because the original manufacturer and vendor for this product in the uk is a company called pyrotenax). A similar product sheathed with metals other than copper is called mineral insulated metal sheathed (mims) cable.

Mi cable is made by placing copper rods inside a circular copper tube and filling the intervening spaces with dry magnesium oxide powder. The overall assembly is then pressed between rollers to reduce its diameter (and increase its length). Up to seven conductors are often found in an mi cable, with up to 19 available from some manufacturers.

Since mi cables use no organic material as insulation (except at the ends), they are more resistant to fires than plastic-insulated cables. Mi cables are used in critical fire protection applications such as alarm circuits, fire pumps, and smoke control systems. In process industries handling flammable fluids mi cable is used where small fires would otherwise cause damage to control or power cables. Mi cable is also highly resistant to ionizing radiation and so finds applications in instrumentation for nuclear reactors and nuclear physics apparatus.

The metal tube surrounding the conductors effectively shields circuits in mi cable from electromagnetic interference. The metal sheath provides protection against accidental contact with energised circuit conductors.

Mi cables may be covered with a plastic sheath, coloured for identification purposes. The plastic sheath also provides additional corrosion protection for the copper sheath.

Purpose and use

mi cables are used for power and control circuits of critical equipment, such as the following examples:

• nuclear reactors

• air pressurisation systems for stairwells to enable building egress during a fire

• hospital operating rooms

• fire alarm systems

• emergency power systems

• emergency lighting systems

• temperature measurement devices; rtd's and thermocouples.

• critical process valves in the petrochemical industry

• public buildings such as theatres, cinemas, hotels

• transport hubs (railway stations, airports etc.)

• mains supply cables within residential apartment blocks

• tunnels and mines

• electrical equipment in hazardous areas where flammable gases may be present e.g. Oil refineries, petrol stations

• areas where corrosive chemicals may be present e.g. Factories

• building plant rooms

• hot areas e.g. Power stations, foundries, and close to or even inside industrial furnaces, kilns and ovens

mi cable fulfills the passive fire protection called circuit integrity, which is intended to provide operability of critical electrical circuits during a fire. It is subject to strict listing and approval use and compliance

typical specifications

maximum voltage 600 or 1000 volts

current rating 18 - 450 amperes

conductor area 1.0 – 240 mm²

copper sheath area 5 – 70 mm² effective

number of cores 1,2,3,4,7,12,19

overall diameter 5 – 26 mm

minimum bend radius 6 x diameter (3 x diameter if bent once only)

weight 100 – 3300 kg/km, 355 - 11708.4 lbs/mi

twists per metre 0, 20; in many applications no twist is preferred.

Finish bare copper, standard pvc sheath, low smoke and fume (lsf) polymer sheath, various stainless steels, inconel, titanium, and some super alloys.

Colour natural (bare stainless, bare copper), white, black, red, orange

maximum operating temperature

continuous - exposed to touch 70 °c

continuous - not exposed to touch; pvc-sheathed 90 °c

continuous - not exposed to touch; not pvc-sheathed 250 °c

intermittent >1000 °c

(melting point of copper is 1083 °c)