Company Information

Ask for more detail from the seller

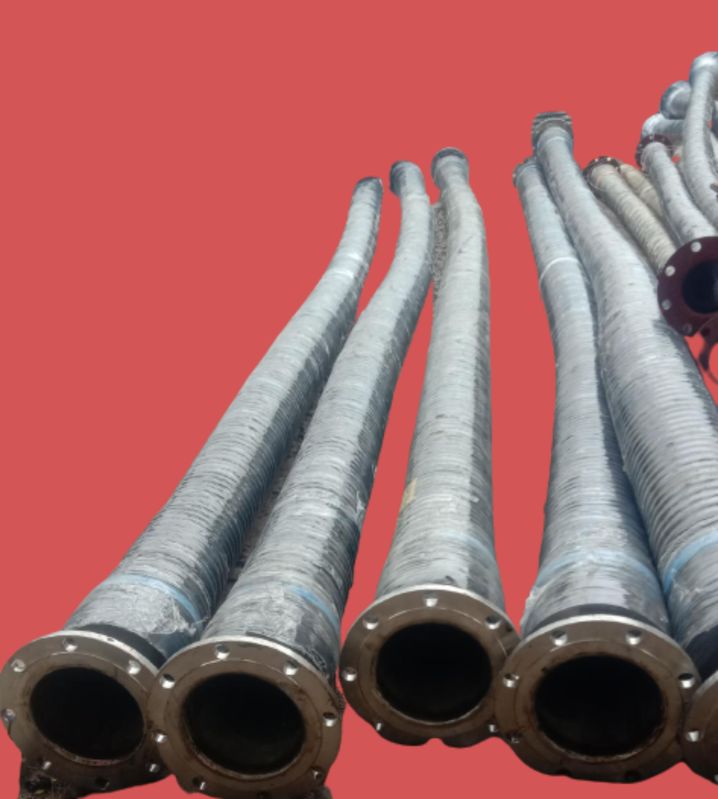

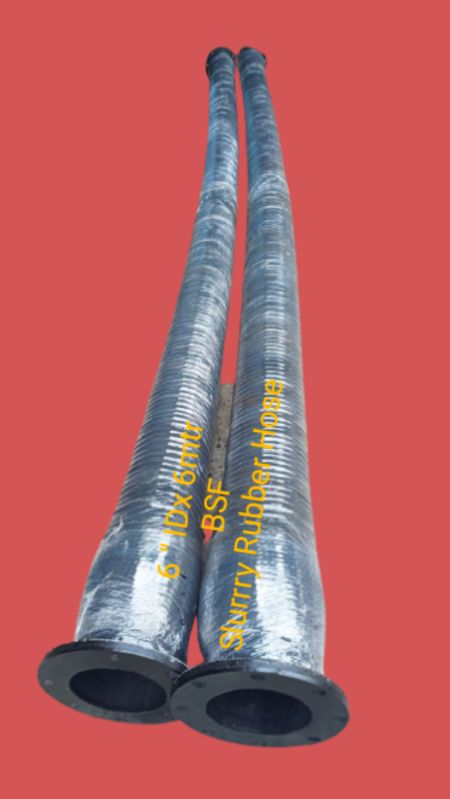

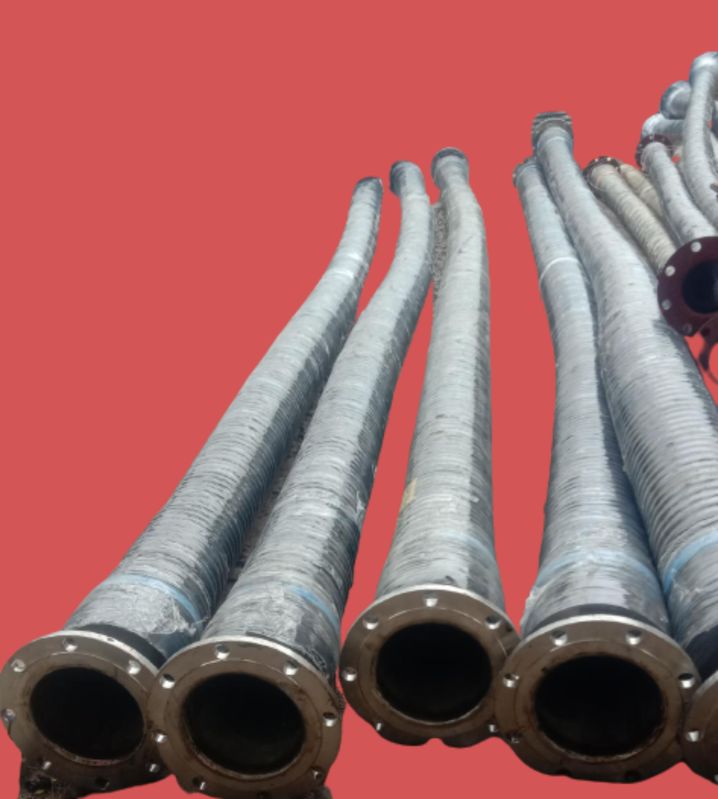

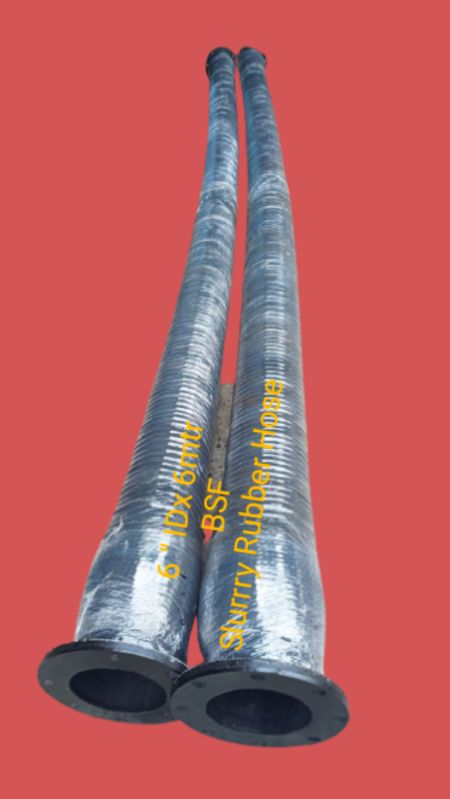

Contact SupplierMining rubber hoses are specialized hoses designed for use in mining operations, particularly in the extraction, processing, and transportation of minerals and materials. These hoses are built to withstand the harsh conditions and demanding applications encountered in the mining industry, including exposure to abrasive materials, high-pressure fluid transfer, and extreme temperatures. They play a critical role in various mining processes, ensuring the efficient and safe transfer of materials, including ore, slurry, and chemicals. Here are some key features and uses of mining rubber hoses: **Key Features:** 1. **Material:** Mining rubber hoses are typically made from high-quality synthetic rubber compounds or natural rubber. These materials provide flexibility, durability, and resistance to abrasion, corrosion, and harsh chemicals. 2. **Reinforcement:** To handle the high pressures and structural stresses involved in mining operations, these hoses are reinforced with multiple layers of high-strength materials, such as textile fabric, steel wire, or synthetic fibers. 3. **Inner Lining:** The inner lining of the hose is designed to be smooth to facilitate the efficient flow of materials while minimizing friction and abrasion. 4. **Outer Cover:** The outer cover of mining hoses is robust and designed to protect the hose from external factors, including abrasion, weathering, and environmental conditions. 5. **Size and Diameter:** Mining hoses come in various sizes and diameters to accommodate different flow rates, pressure requirements, and mining applications. 6. **Couplings:** They are equipped with couplings or connectors at both ends, often made of durable materials like aluminum or steel. These couplings allow for secure connections to mining equipment and piping systems. **Types of Mining Rubber Hoses:** Different types of mining rubber hoses are available to meet specific mining industry needs. Some common types include: 1. **Slurry Hoses:** Slurry hoses are designed for transporting abrasive materials, such as ore, sand, and slurry. They are often used in mineral processing plants and for tailings disposal. 2. **Dredge Hoses:** Dredge hoses are used in mining and dredging operations to transport materials from underwater locations to the surface. 3. **Chemical Hoses:** These hoses are resistant to a wide range of chemicals and are used for transferring chemicals and acids within mining facilities. 4. **Water Suction and Discharge Hoses:** Water hoses are employed for various water-related tasks in mining, such as dewatering pits and transporting water to processing facilities. 5. **Air and Gas Hoses:** Air and gas hoses are used for pneumatic tools, ventilation, and other air and gas applications in mining operations. **Applications:** Mining rubber hoses are used in various mining applications, including: 1. **Material Transport:** They transport mined materials, including ores, minerals, coal, and aggregates, from the extraction point to processing facilities or transport vehicles. 2. **Dewatering:** Hoses are used for dewatering operations in underground mines and open-pit mines to remove excess water and maintain safe working conditions. 3. **Slurry Handling:** Slurry hoses transport abrasive and corrosive slurries from mining processes to disposal or treatment sites. 4. **Tailings Management:** Hoses are employed for the safe and efficient disposal of tailings, including the transportation of tailings from processing facilities to tailings ponds. 5. **Chemical Handling:** In chemical processing and refining, mining hoses handle the transfer of various chemicals used in the extraction and refining processes. Proper selection, installation, and maintenance of mining rubber hoses are essential to ensure their longevity and safe operation in the mining industry. They should be chosen based on factors such as material compatibility, pressure rating, temperature range, and applicat