-

Supply Type

Manufacturer, Exporter, Supplier

Preferred Buyer From :

All over the world

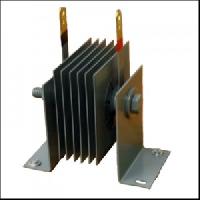

TRUs impress DC Currents in to the Carbon-steel/steel structure to be protected in opposite direction to the galvanic corrosion currents & protects the structure from corrosion.

To obtain the optimum level of protection under varying conditions, it is necessary to vary the impressed current continuously so as to maintain a constant level of protective potential at the structure. This continuous monitoring and control can be achieved by providing an automatic control for the cathodic protection system.