Company Information

Ask for more detail from the seller

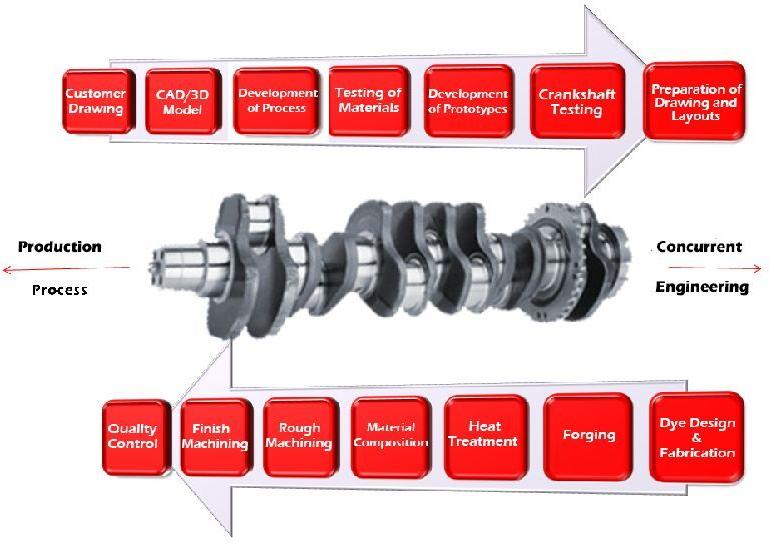

Contact SupplierPRODUCTION PROCESS

Die Design & Fabrication :

The Design & Fabrication of all type of dies are done through exporting the 3D Model into our Die machining centre.

Forging :

The crankshafts are forged in our 16000 T hammer / 4000 T Press as per requirement & customer specification.

Heat Treatment :

The crankshafts undergo a heat treatment process (H & T) & 100% Crack testing (Magnaflux) before we initiate machining of the same.

Material composition :

The material composition & properties are perfectly checked prior to machining in our R&D Laboratory & testing centre.

Rough machining :

Initially Facing & Centering, Turning & Milling & Oil Hole Drilling is carried out on the CNC Machines in the Rough Machining Unit.

Finish Machining :

The Finish Machining Unit consists of CNC grinding, dynamic balancing, post grinding operations, superfinishing & Accessory Product and Assembly.

Quality Control :

The R&D Laboratory & Testing Centre consisting of metallurgical testing, Crack Testing, Fatigue/durability testing, Dimensional testing, etc ensures that every crankshaft leaving our shop floor is 100% quality checked.

CONCURRENT ENGINEERING

Customer Drawing :

Crankshafts of any applications can be made according to drawing or sample. Through these customer specifications we receive the relevant data required for development.

CAD/3D Model :

The crankshaft drawings & specifications are developed in our CAD or 3D software.

Development Of Processes :

The company has gained expertise in manufacturing of crankshafts for more than 25 years in respect to process of material selection, heat treatment, surface treatment,etc.

Testing of Material :

Material testing is done in our R&D & Metallurgical laboratory. The Use of materials is decided depending upon the chemical composition as per engine running type or if specified in Customer drawing.

Development of Prototype :

We have a prototype division where entire process of manufacturing is done on a parallel & flexible line without affecting the series of production.

a) Forging: The crankshafts are forged in our 16000 T hammers & up to a length of 2.5 metres. The crankshafts undergo a heat treatment process (H & T) & 100% Crack testing (Magnaflux) before we initiate machining of the same.

b) Machining: All machining such as Turning, drilling, milling, threading, etc are done on our automated CNC machines.

c) Dynamic Balancing & Final Assembly: The crankshafts are dynamically balanced & finally Counterweights & gears are installed if required. Then the crankshafts are ready to install on on the engine

Crankshaft Testing :

The company has an in-house testing centre & R&D laboratory where crankshafts are subject to various tests & the tests are then collected to understand the future performance of the crankshafts

Preparation of Drawings/Layouts :

As the conclusion of our process of Concurrent Engineering, there is a complete documented solution in terms of drawings/layouts for the production process