Company Information

Ask for more detail from the seller

Contact SupplierCheck valves, or non-return valves, are installed in pipeline systems to allow flow in one direction only. They are operated entirely by reaction to the line fluid and therefore do not require any external actuation. In this text, the expected, or desired direction of flow is termed 'forward flow', flow in the opposite direction is 'reverse flow'.

There are a number of reasons for using check valves, which include:

Protection of any item of equipment that can be affected by reverse flow, such as flow meters, strainers and control valves.

To check the pressure surges associated with hydraulic forces, for example, water hammer. These hydraulic forces can cause a wave of pressure to run up and down pipe work until the energy is dissipated.

Prevention of flooding.

Prevention of reverse flow on system shutdown.

Prevention of flow under gravity.

Relief of vacuum conditions.

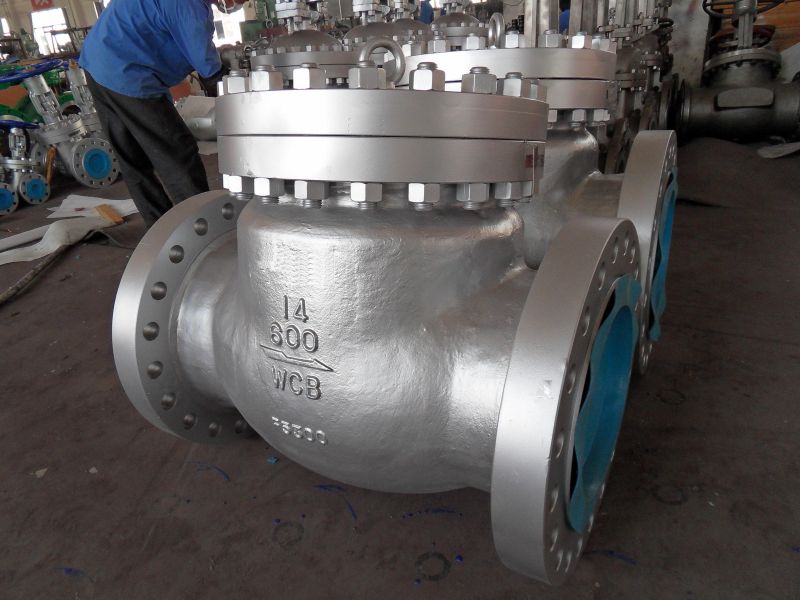

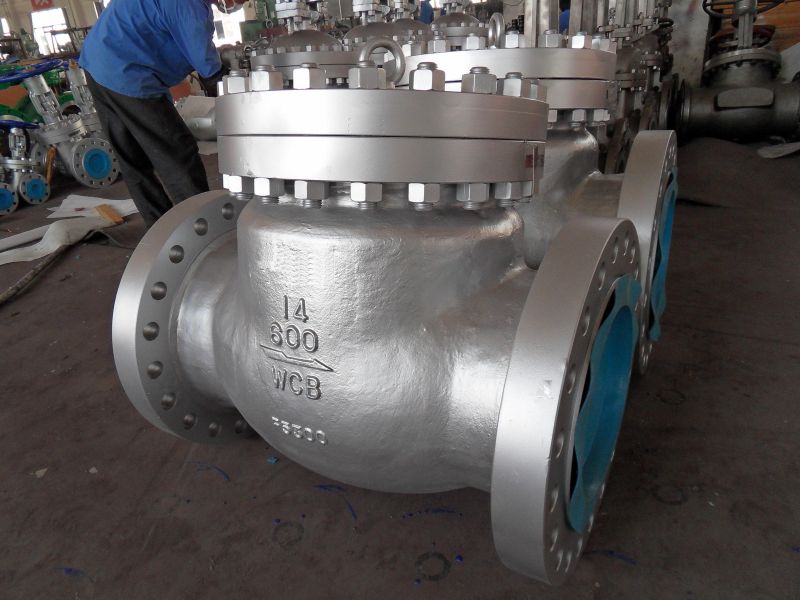

Construction of a NRV Check Valve

The Swing Check Valve is a one-piece body, top entry design for reliable operation and extended seat seal life. Top entry construction allows field service and in-line maintenance if necessary.

All major components of the check valve are normally made from cast and wrought forms, allowing the use of a variety of widely accepted materials. The full bore to API-6D assures unrestricted flow and allows pigging and hot tapping.