Listing ID #4112627

Company Information

Ask for more detail from the seller

Contact Supplier|

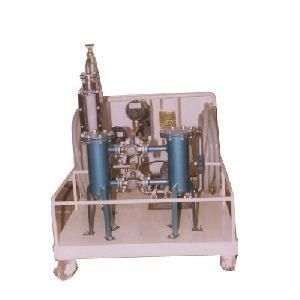

OIL FILTRATION PLANTS CAN BE SUCCESSFULLY MODIFIED & AUTOMATED FOR VARIABLE FLOW RATE.

|

|||||||||||||||||||||||||||||||||||

| A brief description is given for your reference. | |||||||||||||||||||||||||||||||||||

| INLET & OUTLET PUMPS : | |||||||||||||||||||||||||||||||||||

|

The pump will be driven by suitable sized AC drive to control the flow rate. By using these settings we can control the flow rate from i.e. If Plant is 6000 LPH then it will vary from 1000 LPH to 6000 LPH.

|

|||||||||||||||||||||||||||||||||||

| HEATER TANK : | |||||||||||||||||||||||||||||||||||

| It is also necessary to select proper heat output for variable flow rates. This will avoid localized heating of oil for small flow rates. This section will incorporate PLC which will control the heaters. PLC will be used for control of heater groups, once certain flow rate has been selected, heaters will be configured automatically to suit that flow rate. This control panel will be designed for reliable & trouble free operation. By using the above system the major benefit is to have a single machine instead of different models for different capacities. |

|||||||||||||||||||||||||||||||||||

|

In this case, flow rate can be kept variable from 1000 LPH to 6000 LPH. Power saving of 30% can be achievable by using this system as compared with traditional oil filter system designs.

|

|||||||||||||||||||||||||||||||||||

| OPERATIONAL & PROCESS AUTOMATION | |||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||