Listing ID #4133033

Company Information

Ask for more detail from the seller

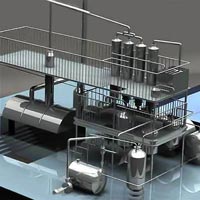

Contact SupplierOil milling is an art. Care has to be taken while expelling the oil to ensure maximum oil recovery with minimum power consumption; cake should not be burnt protein should not be damaged, color fixation of oil should not take place, minimum heat should be generated while expelling; moisture should not find its way with oil, filtration should be in such a manner that no cake particles remain in contact with oil, thus FFA of oil should not increase.

Seeds should be cooked properly and conveying should be provided to make- operation totally mechanical. TROIKA design takes care of all these aspects, added is the decades of experience. Well-designed plant layouts, trouble free maintenance, ease of operation, low utility consumption makes TROIKA oil mill a viable proposition. Oil milling can be only prepressing in which case seeds are lightly pressed, and which leaves about 14% to 18% oil in the pressed cake. This method results in higher capacity; lower power consumption, lower wear & tear / maintenance. But it also lowers recovery of oil, it is recommended when the buyer has his own solvent extraction line, so that balance oil is recovered during solvent extraction process.

In the second method, when pressed cake is to be sold in the market, it is desirable to recover the maximum oil. Hence double pressing system is recommended. Here either in the same screw press -two stage pressing is carried out or prepressed cake from first stage screw press in sent for re -second pressing to other screw press. The oil left over after double pressing varies from 7% to 9% depending on the oil seed and extent of pressing.

Any oil-bearing seeds can be processed in oil mill, specially preparatory equipment are recommended prior to expelling. For Cotton Seed, Sunflower Seed, Groundnut Seed. Decorticators Are Recommended, for copra shredders and for Palm kernel hammer mills are required as preparatory equipment.