Company Information

Ask for more detail from the seller

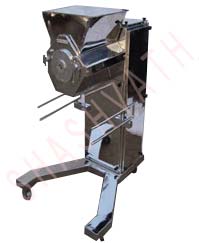

Contact SupplierWe are the leading manufacturers and suppliers of Oscillating Granulator from Thane, Maharashtra. Oscillating granulator is used for granulating the material into desired particle size. The efficiency of our granulator is impressively high and the installation is very easy. The maintenance cost is also comparatively less and noise levels of the oscillating granulator are reduced as per the norms specified internationally.

Construction :

Salient Features

Robust, Simple & Compact Design.

Stainless Steel Construction.

Easy Installation in Production Line.

Oscillating Rotor Motion.

High Output.

Uniform Granules, Less Fines.

Low noise level as per international norms.

Maintenance Free.

Easy for Cleaning.

Optional Features :

Flame proof motor and Push Button Station.

Inline granulation with Roll compactor & Tipper with FBD Bowl.

Safety Features : Limit switch at charging hopper & over load relay protection.

Vertical Model | |

|---|---|

| Hopper Capacity | 15 & 30 Ltrs. (8” & 12”) |

Screen Area | 8” x 12” respectively |

Output | 30 to 100 / 200 Kgs/Hr (Approximately Depending Upon the Material) |

Power Supply | 1 H.P (8”) 1.5 H.P. (12”). 1440 R.P.M , 440 Volts, 3 Phase, 50 Cycles A.C. |

Approximate Dimensions | 28” X 16.5” X 48” |

Net Weight | 210 Kgs |

Gross Weight | 295 Kgs |

Horizontal Model | |

Hopper Capacity | 34 Ltrs. |

Screen Area | 12.4” X 14.3” Length |

Output | 30 TO 200 KGS/HR (Approximately Depending Upon the Material) |

Power Supply | 1.5 H.P 1440 R.P.M , 440 Volts, 3 Phase, 50 Cycles A.C. |

Approximate Dimensions | 28” X 16.5” X 48” |

Net Weight | 210 Kgs |

Gross Weight | 295 Kgs |