Company Information

Ask for more detail from the seller

Contact SupplierThe cliche is the carrier of the print motif.

Various types of plate clichés are used depending on the desired print quality and quantity. The motif is recessed, etched into or washed out of the cliché. In order to assure smooth fitting and printing, the motif should be at a distance of at least 25 mm (1 inch) from the outer edge, and centered on the plate. In the case of long or fine lines, the motif must be at an angle of approx. 5° to 15° to the blade track in order for the doctor blade not to dip too low and scoop out too much ink. Numerous trials have shown that an etching depth of 25 μm is optimal for pad printing. Since the pad can only transfer a limited quantity of ink, a greater depth is pointless. At an etching depth of 25 μm, the pad only picks up an ink film of 12 μm. The rest remains in the depressions of the cliché. Because the ink film consists of approx. 40 % to 60 % thinner, which evaporates during the transfer and drying, the actual thickness of the ink film left on the substrate comes to around 5 μm – 8 μm, in some cases, as little as 2 μm. As an exception to the above statement, very fine fonts are etched at approx. 15 μm, and very large motifs, at approx. 30 μm. For very large surfaces, the dip of the doctor blade can be avoided by additionally copying a fine screen into the motif.

Steel clichés have a very long life expectancy, typically around 700,000 to 1,000,000 or more imprints can be expected. While nylon clichés have a much shorter life cycle, typically around 10,000 to 40,000 imprints depending upon various production factors. Obviously, steel plates are more expensive than nylon plates, but many customers choose steel over nylon for ease of production.

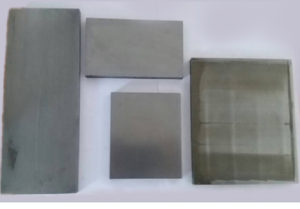

Different types of pad printing plate clichés :