Company Information

Ask for more detail from the seller

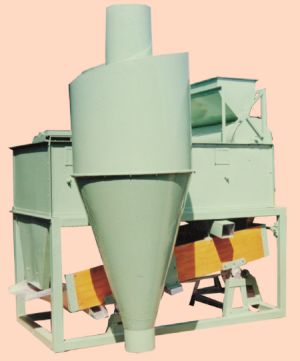

Contact SupplierPre cleans all cereals, Paddy, Rice, Wheat, Pulses, other seeds etc. Equipped with Scalper drum to remove Roughage, tield trash, straw and other large impurities. Aspirator blows off Dust, Immature grains and light impurities into the cyclone. Double Deck screening removes fine as well as coarse impurities. The exclusive rotating scalping reel removes roughage, field trash and other foreign materials. The product is spread over the full width of the machine by damper control. The product is fed evenly along the outside length of a slowly rotating scalper reel. As the reel rotates the product passes through the mesh but large impurities such as straws large rock pieces, pieces of wood etc. are carried over the top of the reel to be discharged. Aspiration removes dust, chaff, immature grains and other fine impurities etc. The product leaving the scalper reel is guided down through the zig zag baffles into vertical aspiration column where a rising current lifts the lighter material into a front aspiration chamber. In the aspiration chamber the heavy material lifted along with drops into a chute for discharge and Light particles are blown off into a cyclone. The sieving decks are very versatile. The top sieve is always a scalping sieve (removes coarser particles) and bottom sieve is always a sifting sieve (removes tiner impurities) However the sieve in between can be changed to either scalping or sifting. Before the graded material leaves the machine, it passes another air stream at the tail aspiration, where possible ears or light and empty kernels are sucked away into the rear aspiration chamber, where the heavy material lifted along with, drops into a chute for discharge

| Model | Cap. In Paddy/Hr | H.P.each |

|---|---|---|

| MFC 50 | 5 M.T. /Hr. | 5 |

| MFC 100 | 10 M.T. /Hr. | 7.5 |