Company Information

Ask for more detail from the seller

Contact SupplierIndustrial IoT Gateway - SIMATIC IOT2000

An intelligent gateway which harmonizes communication between the various sources of data before analyzing it and forwarding it to the corresponding

recipients. An easy-to-implement solution.

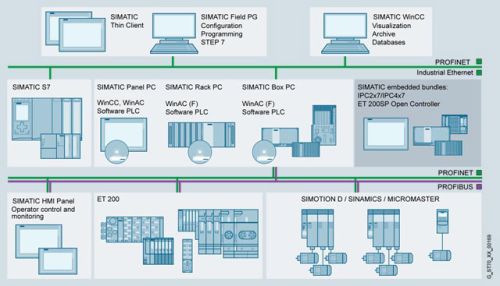

Industrial PC

Our reliable and innovative industrial PCs are the optimal PC hardware platform for PC-based Automation from Siemens.

• Rack PC

• Box PC

• Panel PC

• Tablet PC

• Industrial monitors and thin clients

• Devices for special requirements

• Fully-enclosed IP65 devices

• Devices with stainless steel fronts

• Devices for hazardous areas

• IPC software

• Embedded bundles/software packages

SIEMENS SIMATIC Industrial PC

Our reliable and innovative SIEMENS SIMATIC industrial PCs are the optimal PC hardware platform for PC-based Automation from Siemens.

• Rack PC

SIEMENS SIMATIC Rack PCs are flexible, high-availability industrial PC systems for powerful yet compact applications using 19" technology.

Four device classes are available for different requirements:

SIEMENS SIMATIC IPC347 – high performance at an optimized price

SIEMENS SIMATIC IPC547 – latest technology and maximum performance

SIEMENS SIMATIC IPC647 – maximum compactness combined with maximum industrial functionality

SIEMENS SIMATIC IPC847 – maximum expandability and industrial functionality

• Box PC

SIEMENS SIMATIC Box PCs provide mechanical engineers, plant engineers and control cabinet makers with particularly rugged industrial PC systems for use in powerful yet compact applications.

The following device classes are available for various requirements:

• SIMATIC IPC227 (Nanobox PC): The Box PC with optimized performance in compact design – maintenance-free and rugged

• SIMATIC IPC427 (Microbox PC): The powerful embedded IPC – maintenance-free with versatile configuration

• SIMATIC IPC627/IPC827 (Box PC): The high-end IPC – with maximum performance, functional scope, and expansion capability

• Panel PC

SIEMENS SIMATIC Panel PCs are suitable thanks to their high industrial compatibility for use in control cabinets, consoles and control panels, as well as

directly on the machine. Typical areas of application can be found in both factory and process automation.

There is a broad range of robust, high-performance SIEMENS SIMATIC Panel PCs available for different requirements.

• Tablet PC:

The SIEMENS SIMATIC Industrial Tablet PC taps new application areas within the scope of Industry 4.0. Considered for industrial use, the SIEMENS SIMATIC ITP1000 can convince with its many functions in day-to-day working. Typical applications are in maintenance/service, production and measuring and testing.

• Industrial monitors and Thin Clients

SIEMENS SIMATIC industrial monitors in industry-standard design are fail-safe and durable. You can select one of the two following LCD display ranges:

• SIEMENS SIMATIC Flat Panels or

• SCD monitors.

SIEMENS SIMATIC Thin Clients are low-cost operator control units and support different protocols so that they can be flexibly connected via PROFINET/Ethernet.

Software controller

The SIEMENS SIMATIC S7-1500 Software Controller implements a SIEMENS SIMATIC S7-1500 controller on SIEMENS SIMATIC IPC. It is mainly suitable for control solutions in special-purpose machine manufacturing which involve a high-performance implementation of complex control tasks, the integration of PC applications, or the realization of multiple tasks on a single device.

PC-based controllers

PC-based controllers combine the functions of a PC-based software controller with visualization, PC applications and central I/Os (inputs/outputs) in a single, compact device. The SIEMENS SIMATIC ET 200SP Open Controller is an industrial PC with the design of the ET 200SP I/O system and a pre-installed SIEMENS SIMATIC S7-1500 Software Controller.

• Application examples

Unit-type cogeneration unit

When redesigning unit-type cogeneration units, the automation approach should also be updated. The objective was to execute all control, visualization and archiving tasks which were previously handled by a PLC and a PC on a compact unit. Space was to be saved in the control cabinet, and the administration and training requirements reduced. At the same time a rugged, maintenance-free device was required which can also be easily connected over the Internet. The advantages of the solution with SIEMENS SIMATIC PC-based Automation:

• Microbox PC as a rugged, compact fixed system

• Control, visualization and archiving of the process parameters in one device

• Space and cost savings thanks to integration of several tasks on a single fixed industrial PC

• Previously: one PLC and one visualization PC

• Easy and quick access to the embedded IPC over the Internet

Measurement of foil thickness

During the manufacture of plastic foils, an extremely accurate and uniform foil thickness over the entire width is a decisive quality principle. For this reason, a measuring head with radioactive source moves back and forth above the foil and perpendicular to the continuously transported reel, and a sensor moves underneath the foil.

From the reduction of the radiation, the foil thickness can be determined exactly at each position by extensive mathematical calculations, and deviations from the reference thickness can be compensated.

The advantages of the solution with SIEMENS SIMATIC PC-based Automation:

• Visualization is performed using WinCC, and control using WinAC RTX on a PC.

• Complex mathematical algorithms are required for evaluation of the extensive measured data.

• These are meaningfully implemented in the high-level language C++. Seamless and high-performance integration of these algorithms into the STEP 7 program is via the ODK (Open Development Kit).

• Data exchange between WinAC RTX and WinCC, for visualization of the extensive measured curves, takes place very quickly via the hard drive cache. This functionality was also implemented via the ODK.

• Interconnection of the standardized technology function is via CFC (Continuous Function Chart).

Innovative PC-based solution with safety for solar panel production

For a new plant for the production of solar panels, the existing highly heterogeneous concept is to be replaced by a new, state-of-the-art automation solution which can cover the complete demands in a compact and integrated way.

There are increased performance and memory requirements due to the increased complexity of the system. The Siemens PLC should also be able to provide the specified safety functions (emergency stop, access protection to hazardous areas).

Various bus systems must be linked in plant 3. Also a customer-specific Windows application is to be used on the selected systems and therefore the connection to a higher-level MES system has to be implemented.

The system is designed for high throughput and three-shift operation.

The advantages of the solution with SIEMENS SIMATIC PC-based Automation:

• Very high performance and available memory with the SIEMENS SIMATIC Modular Embedded Controller EC31-RTX F. In the RTX F version (worldwide the first software PLC with safety functionality), the EC31 offers full coverage of all safety requirements in the plant. This system is integrated seamlessly in Totally Integrated Automation and enables effective, plant-wide engineering.

• Thanks to its openness (Open Development Kit), WinAC RTX on the host SIEMENS SCADA industrial PC offers the possibility for integrating a Windows customer application with very little effort, and is thus used as a data concentrator (process quality/diagnostic data), and communication with the host MES system is also implemented in combination with WinCC (SIEMENS SCADA).

• Industry-standard products from the SIEMENS SIMATIC range offer maximum quality for 24/7 round the clock operation.

Safe transfer at sea

For transferring persons at sea to wind energy plants or oil platforms, a Dutch company has developed a six-legged platform on hydraulic cylinders.

This platform is basically an upside-down flight simulator, and allows safe transfer from a ship even in bad weather.

A SIEMENS SIMATIC S7 Modular Embedded Controller (S7-mEC) with fast I/O cards measures the movements of the ship and controls the extending or retracting of the cylinders so that all movements are compensated.

The advantages of the solution with SIEMENS SIMATIC PC-based Automation:

• Fault-tolerant SIEMENS SIMATIC S7-400H in redundant design for general control tasks

• Two lower-level SIEMENS SIMATIC S7 Modular Embedded Controllers which meet the requirements for high speeds, integration of fast I/O cards, and a flexible, modular and rugged design.

• An integrated programming environment with SIEMENS SIMATIC STEP 7

• Automation products from Siemens comply with the stringent requirements of the offshore sector

PC-based machine data acquisition optimizes the production of farming machinery

To introduce more efficient, resource-saving and therefore cost-effective production processes in the factory, a leading farming machinery manufacturer has integrated a central, plant-wide machine data acquisition system using Panel PCs. Due to the need for retrofitting in the existing environment, flexible and space-saving installation of the Panel PCs was paramount.

More than 200 fully enclosed SIEMENS SIMATIC IPC477 PRO Panel PCs for central machine data acquisition, with communications interfacing to the production machinery and the production planning computer. Mounting of the Panel PCs directly at the machine without additional control boxes on stand-alone columns.

The advantages of the solution with SIEMENS SIMATIC PC-based Automation:

• Improved efficiency by optimizing the complete production organization through a high degree of uniformity.

• Minimized use of resources (less paper is required in production).

• Simple, low-cost retrofitting of the Panel PC directly in production on a stand, without the installation of an additional operator console.

PC-based control in automotive test rigs

Test rigs in the automotive industry require uncomplicated operation and high quality.

A high-performance system is required in the control, processing, archiving and visualization of measured data which can also provide openness and flexibility for connection to different bus systems and for the use of software.

The advantages of the solution with SIEMENS SIMATIC PC-based Automation:

• Flexible, easy-to-service and maintenance-friendly system with Windows in conjunction with CPU 1500S Software Controllers.

• Reduction in integration overhead thanks to integral interfaces such as PROFINET, PROFIBUS, Ethernet, CAN, and the flexibility provided when using modules for different bus systems, e.g. PCIe/104.

• System availability concept ensures round-the-clock operation and reduced downtime costs.

• Fan-free, temperature-resistant operation up to 60 °C saves additional cooling measures.

• High investment security through long-term availability of the components.

PC-based control in the semiconductor industry

In the semiconductor industry, high quality and fault-free operation round-the-clock are decisive criteria. A high-performance system that guarantees fast and precise production of the semiconductors is required for controlling the machines, monitoring the production system, and processing the production data. High flexibility and openness are also required for connecting to the production control system and machine engineering system.

The advantages of the solution with SIEMENS SIMATIC PC-based Automation:

• Compact, rugged industrial PCs with powerful processors and the latest technology enable high processing performance.

• Pre-installed systems save time and costs when incorporated into the overall system.

• WinCC ToolLink-EDA (Equipment Data Acquisition) enables diagnostics of process and machine data in real time.

• System availability concept with integral RAID1 functionality and remote monitoring with SIEMENS SIMATIC IPC DiagMonitor ensures fault-free 24-hour operation.

• High investment security through long-term availability of the components.

• International certification and worldwide support makes global use possible.

Track & trace line controller for industry

In order to conform with new legal regulations, a track & trace system in an existing plant has been extended. The requirement is to test 100 cartons per minute in three-shift operation and to save the data in an SQL database for traceability reasons.

The automation system should be characterized by high ruggedness, but also offer the openness required to connect additional components such as printers and the Machine Vision system.

The advantages of the solution with SIEMENS SIMATIC PC-based Automation:

• Compact automation solution consisting of Microbox PC embedded industrial PC, PLC with preinstalled and ready-to-use PLC software and visualization with WinCC

• Control of the entire track & trace system and interfacing to the control system.

• Open solution with the help of the WinAC ODK (Open Development Kit) thanks to a link to an SQL database for managing the serial numbers and other data. • Additional openness and flexibility by connecting printers and vision system.

Retrofit of a woodworking machine – safe!

In the past, machines and plants for wood-working were equipped with specially developed, proprietary controllers. Today, future-oriented standard components are used for retrofit projects. The customer decided in favor of integrating standard automation and safety technology in a single unit with the SIEMENS SIMATIC WinAC RTX F software controller in a fan-free and maintenance-free IPC, the Microbox PC. PROFINET as an innovative fieldbus connects distributed I/O, safety and operator panels quickly and easily